It’s either because reasonably priced large-framed Vespas are extremely difficult to find these days, or scooterisls are all suddenly trying to rekindle their youth that smallframes are becoming more popular of late.

Whatever the reason, the British scooterboys of the 80s successfully butchered the majority of 50 Specials, V100s and Primaveras originally imported in the UK back in the day, but luckily such Vespas have proved the staple diet of commuters in their native Italy and are now being imported by the van load to these shores.

Often unmolested mechanically, reliability being higher on the agenda in Milan than speed, common faults do however include jumping out of gear and knackered clutches the result of years of use in congested cities. We thought it about time therefore to show you inside a smallframe Vespa engine so we set off with our cameras to JB Tuning in Southend where they had a suitably sick Vespa P 125ETS on the bench ready for us to take a closer look at…

A big thanks to the guys at JB Tuning in Southend (01702 545942) for sharing their smallframe expertise with us for this article.

1. Take one smallframe Vespa P125ETS that’s jumping out of gear and put it on the workbench, ready for dissection. Although it’s already on its stand, it’s also a good idea to put blocks ore jack under the rear floorboards to keep the scoot upright when the rear wheel is removed.

2. The carburettor on a smallframe sits inside the frame so you need to undo the clamp and remove it from the manifold before attempting to drop the engine, otherwise you will break something. Gain access by removing the plastic toolbox that is located in front of the petrol lank.

3. At the rear of the engine is a dowel that is used to locale the two engine halves accurately during reassembly. Gently drive this out and put in a safe place. Next you need to drain the old engine oil out.

4. With the exhaust removed you have access to the rear wheel. On this model there’s a split pin, castle retainer and nut to remove before the wheel can be pulled off. Take care to catch the washer too!

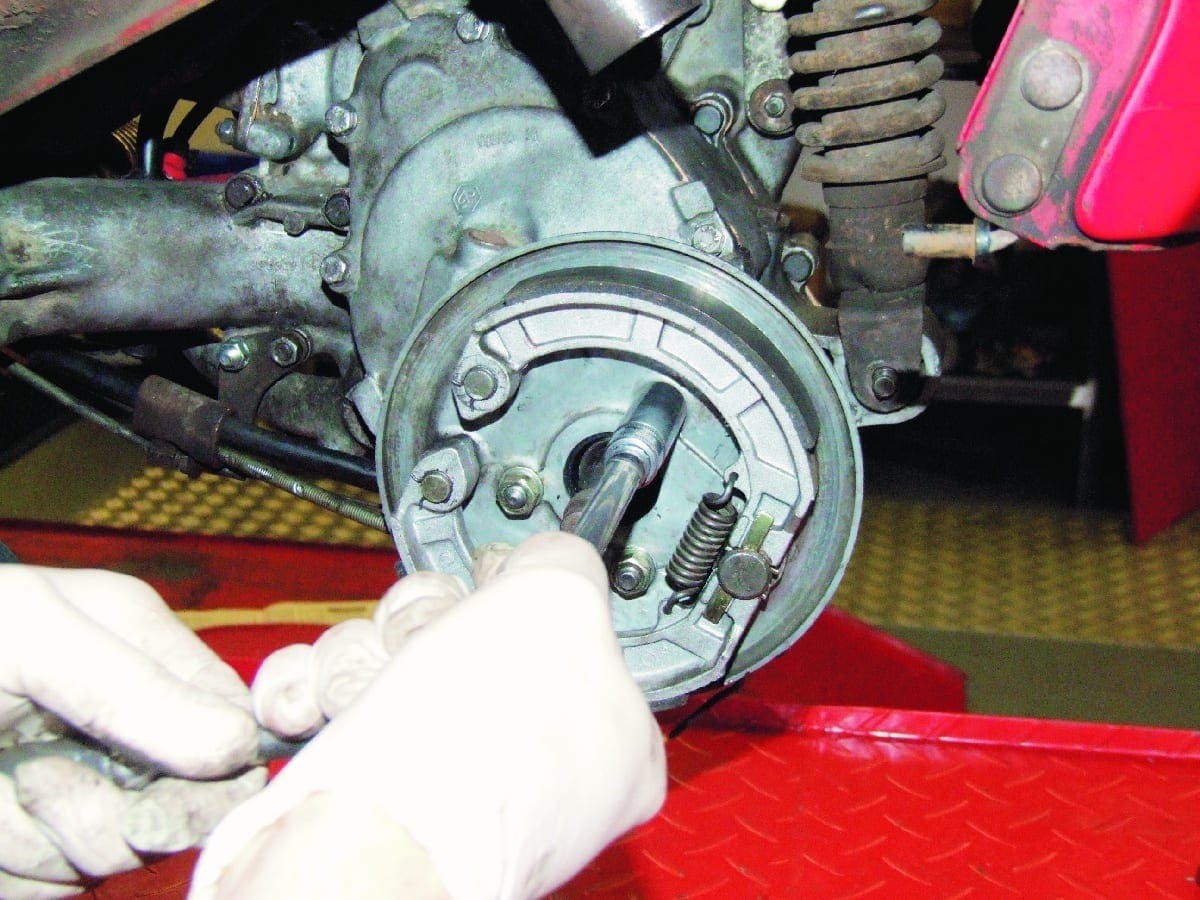

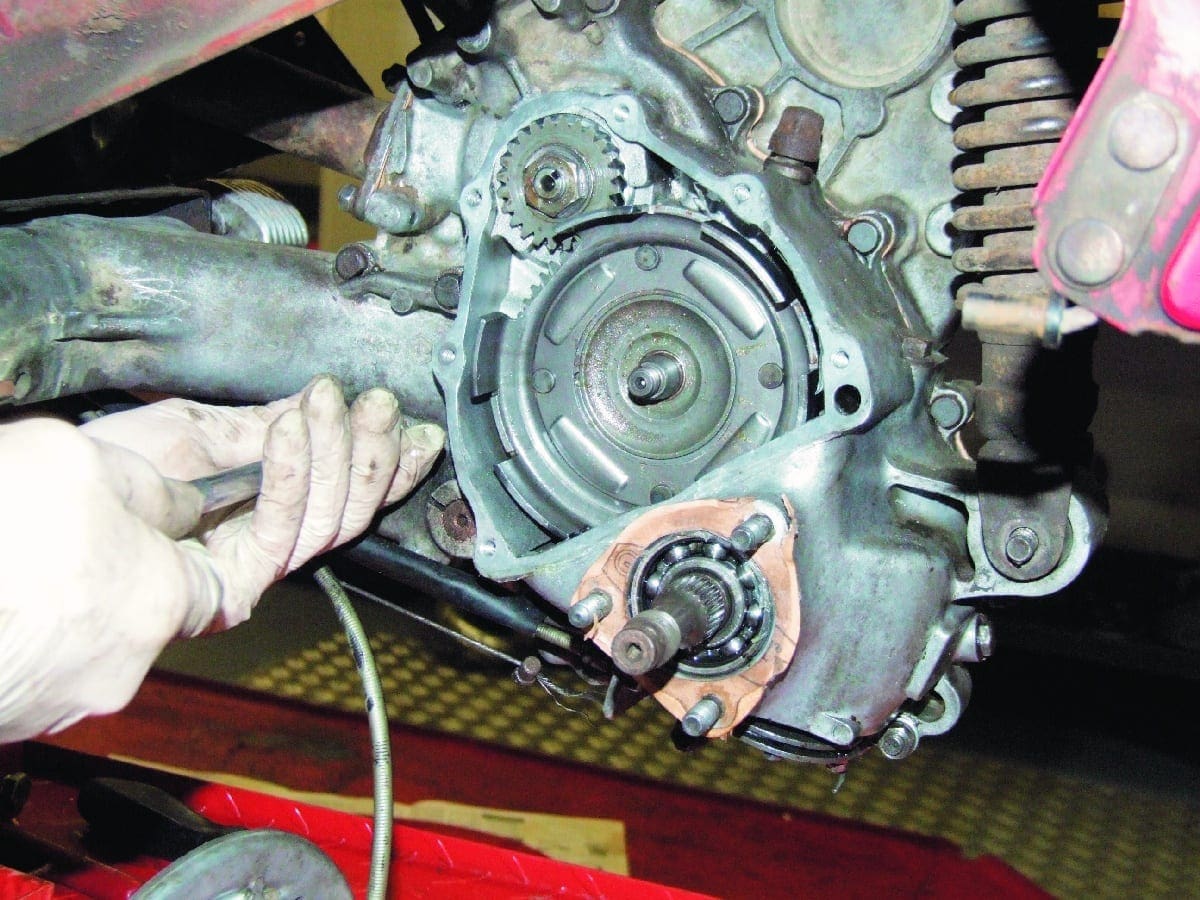

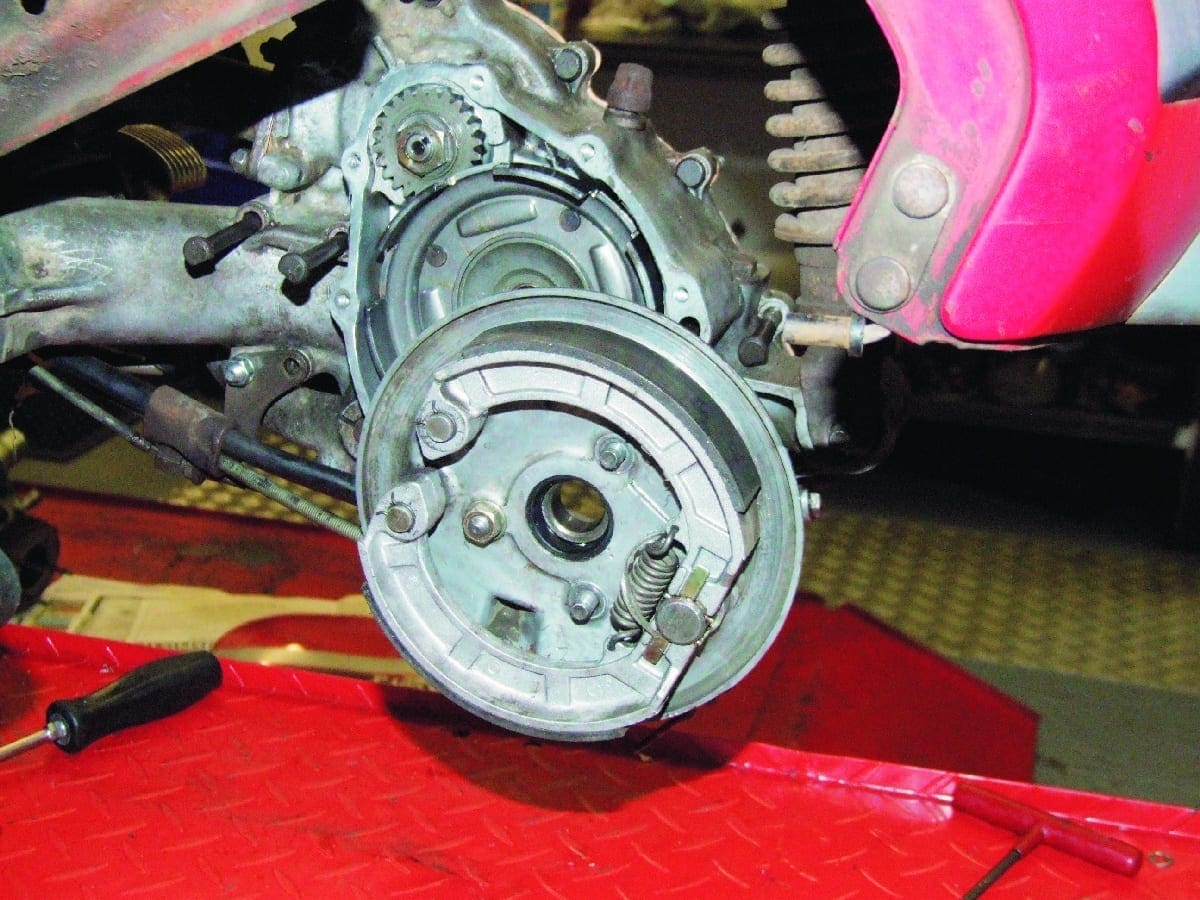

5. Next you need to remove the hub’s backplate (also a bearing retainer), retained by three nuts as shown. The brake shoes can be left in situ, if you wish.

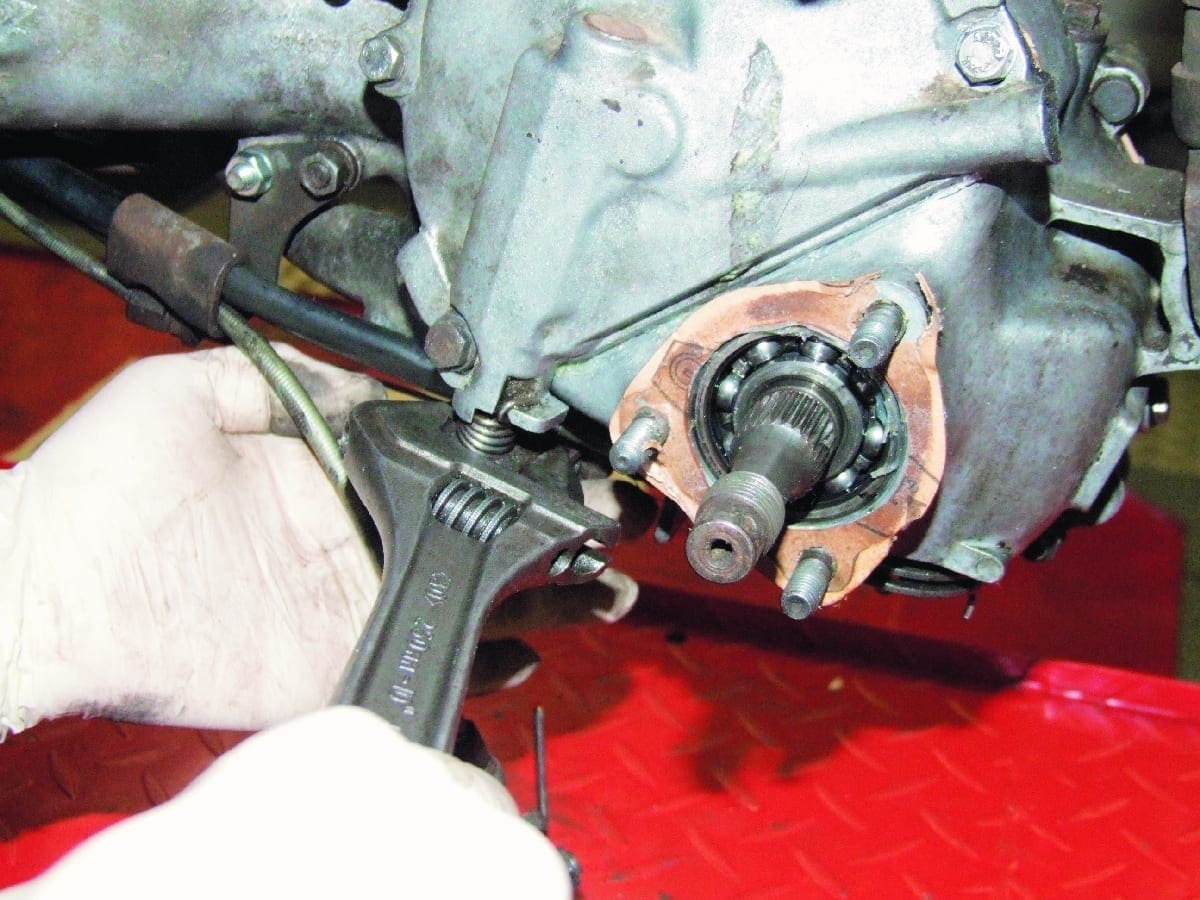

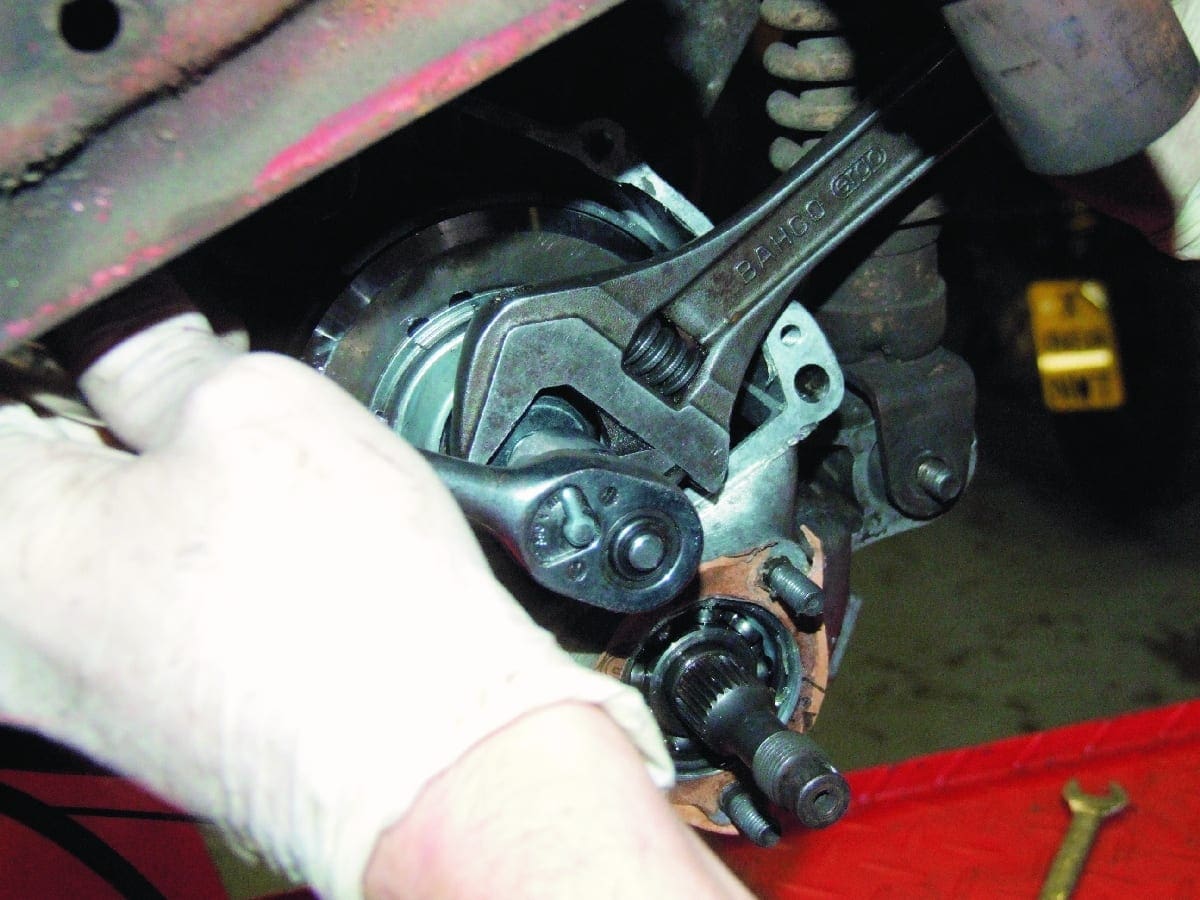

6. If it’s just maintenance that you are performing you may like this little trick to remove the clutch cable without undoing it. Simply tighten an adjustable spanner around the clutch arm and activate it far enough for it to be removed by hand. Note if you are changing the clutch plates the cable will probably have to be readjusted anyway.

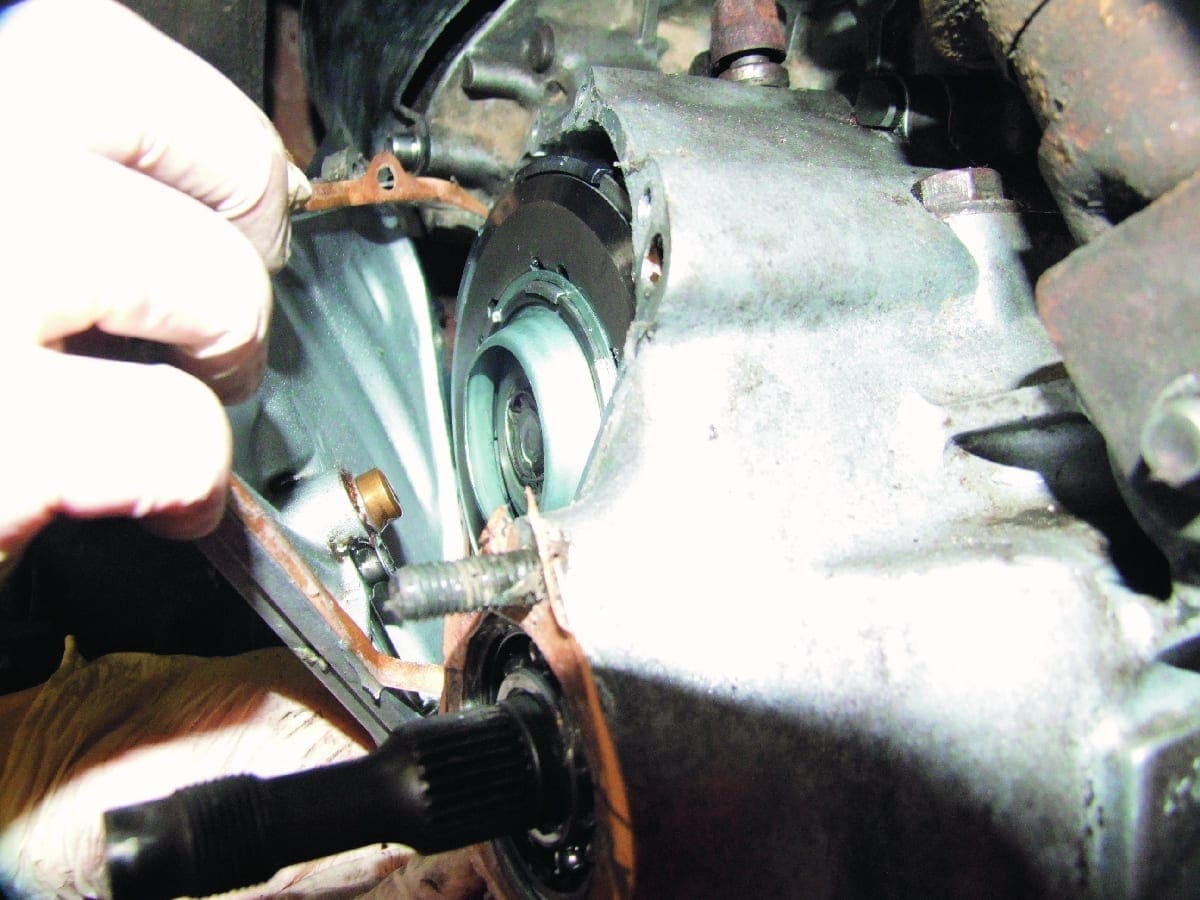

7. Undo the bolts that retain the clutch housing. A tip on reassembly is to use a small handled ratchet so as not to exert too much power and strip threads. Once free, gently ease it away from the casing, making sure you don’t lose the brass plunger inside. Next use a small screwdriver to unclip the pressure plate, then a larger one lo bend back the tab washer locking the holding nut below it.

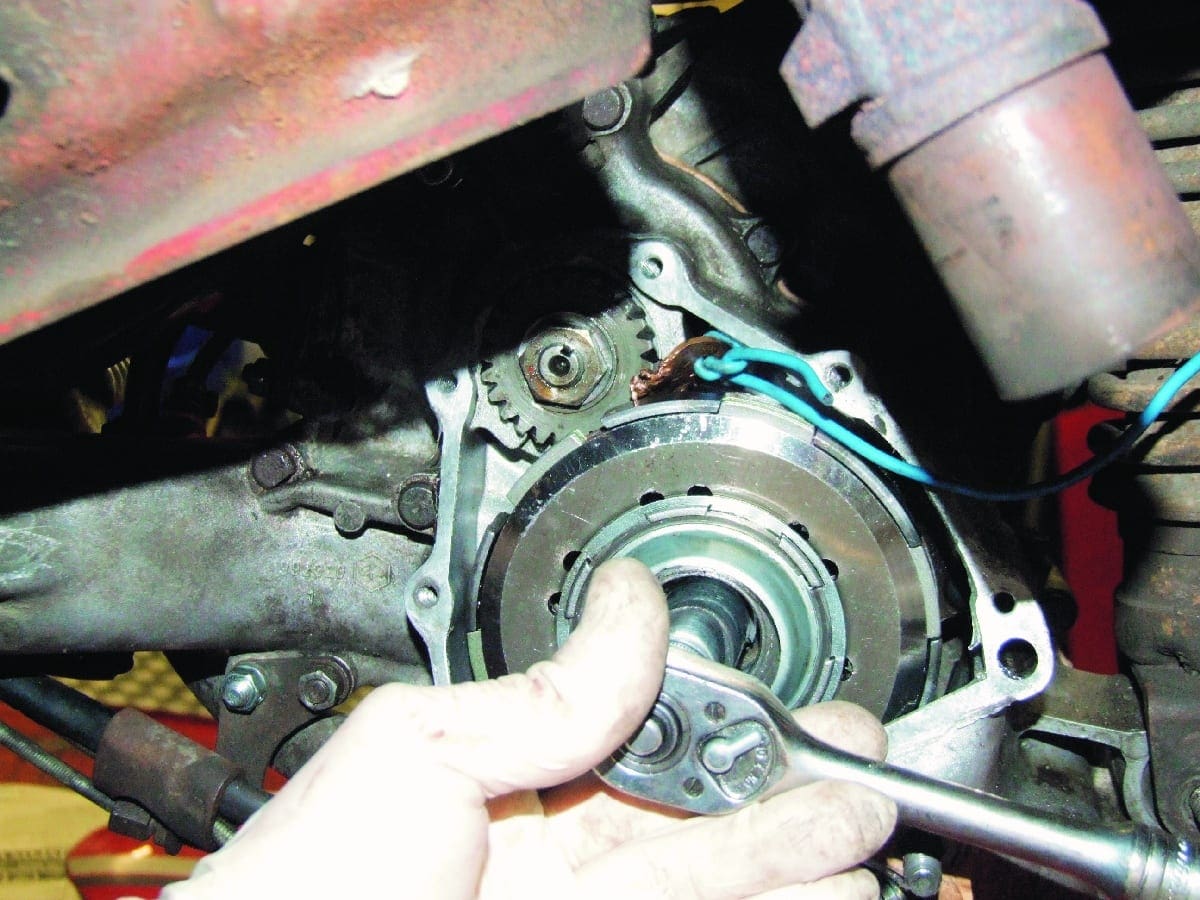

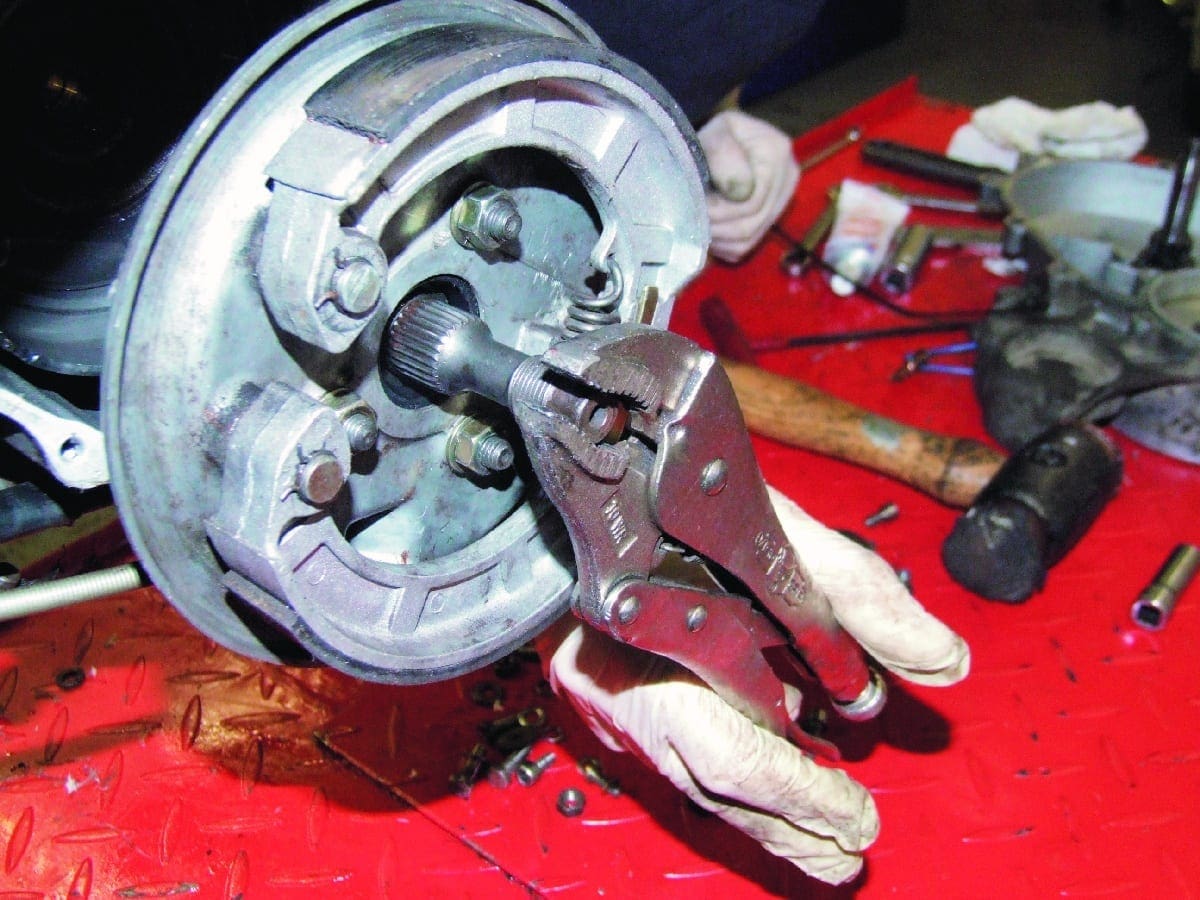

8. Using a flywheel holder to keep the clutch in place as you undo the nut (anti-clockwise) could exert unnecessary tortional force upon the crank. Instead a number of dealers use this little trick, a copper coin wedged between the primary gear and the drive gear. There is a gap in the rear of the clutch basket which when rotated to the top is the easiest place to use the coin.

9. Because the copper coin is the softer metal it will not break anything as it locks the clutch, and you use the wire on the end to fish it out in case it falls. Next use a workshop clutch-pulling tool to gently remove the clutch in much the same way a flywheel puller works.

10. The clutch is a bit fiddly to remove out of the casing, necessitating a bit of a wiggle and patience. Once out though, locating the small Woodruff key is a priority. Sometimes it stays in the engine, but as in this instance it can also come out stuck inside the clutch basket.

11. Using a PX clutch compressor gripped in a vice, lower the clutch onto it, tighten it up to compress it, then remove the retaining circlip.

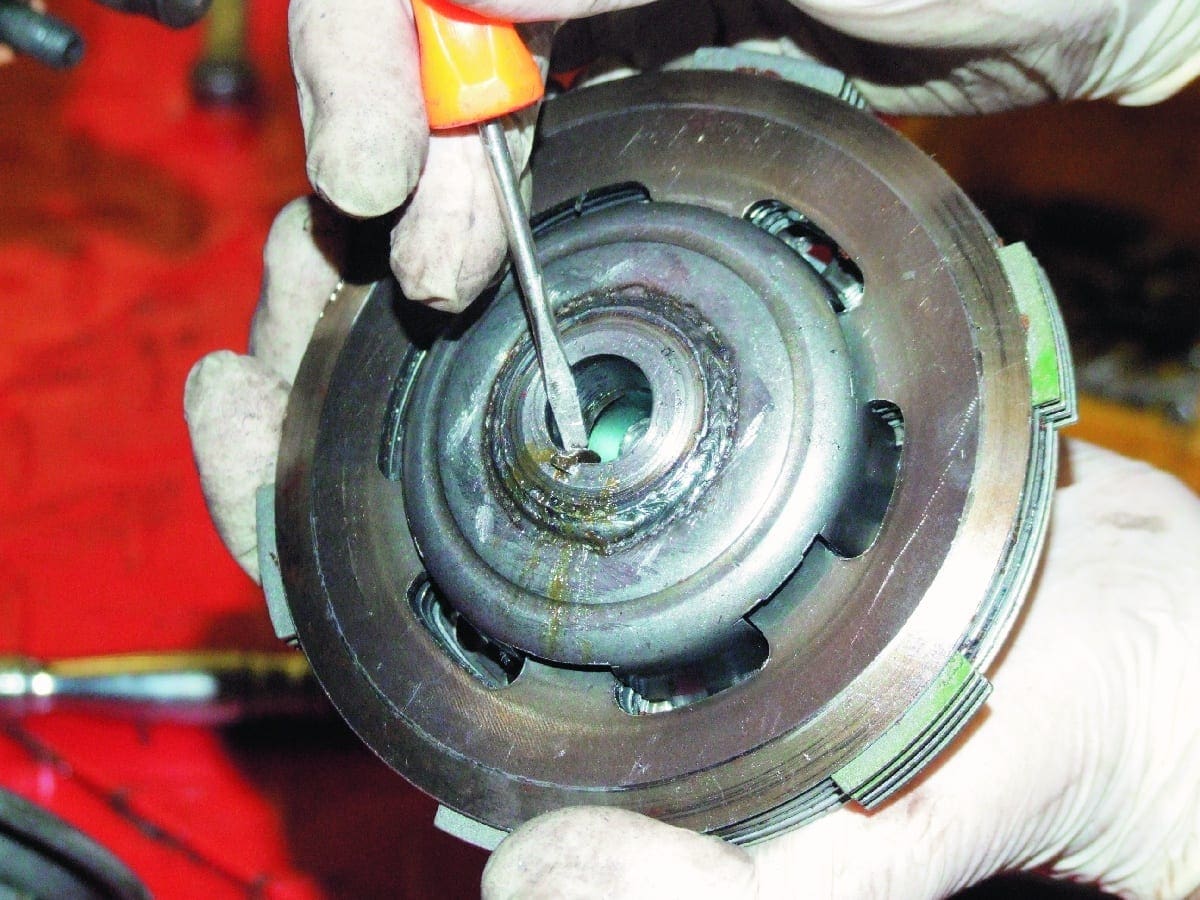

12. Remove the tin ‘oil retaining’ cap on top and you’re left with your average set of plates. Throw the old ones away and reassemble the clutch unit using new plates.

13. One lip is that once the clutch unit is assembled, before you replace it into the engine use a set of adjustable grips to make sure all the plates are sitting ‘true’.

14. A flywheel-holding tool is a worth Investment for any it budding scooter mechanic as the lack of one ALWAYS leads to snapping fins. A decent flywheel puller is also worth the money too as both tools make life so much easier.

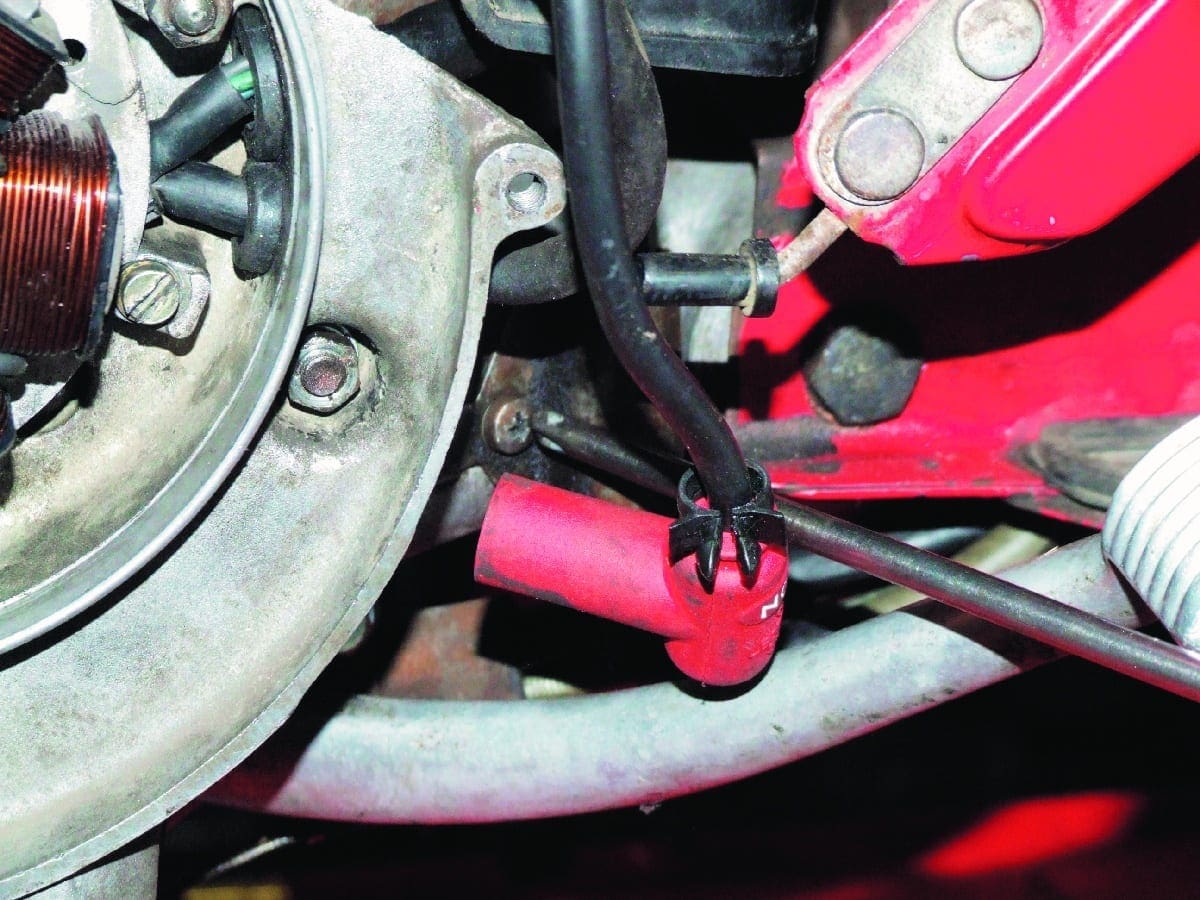

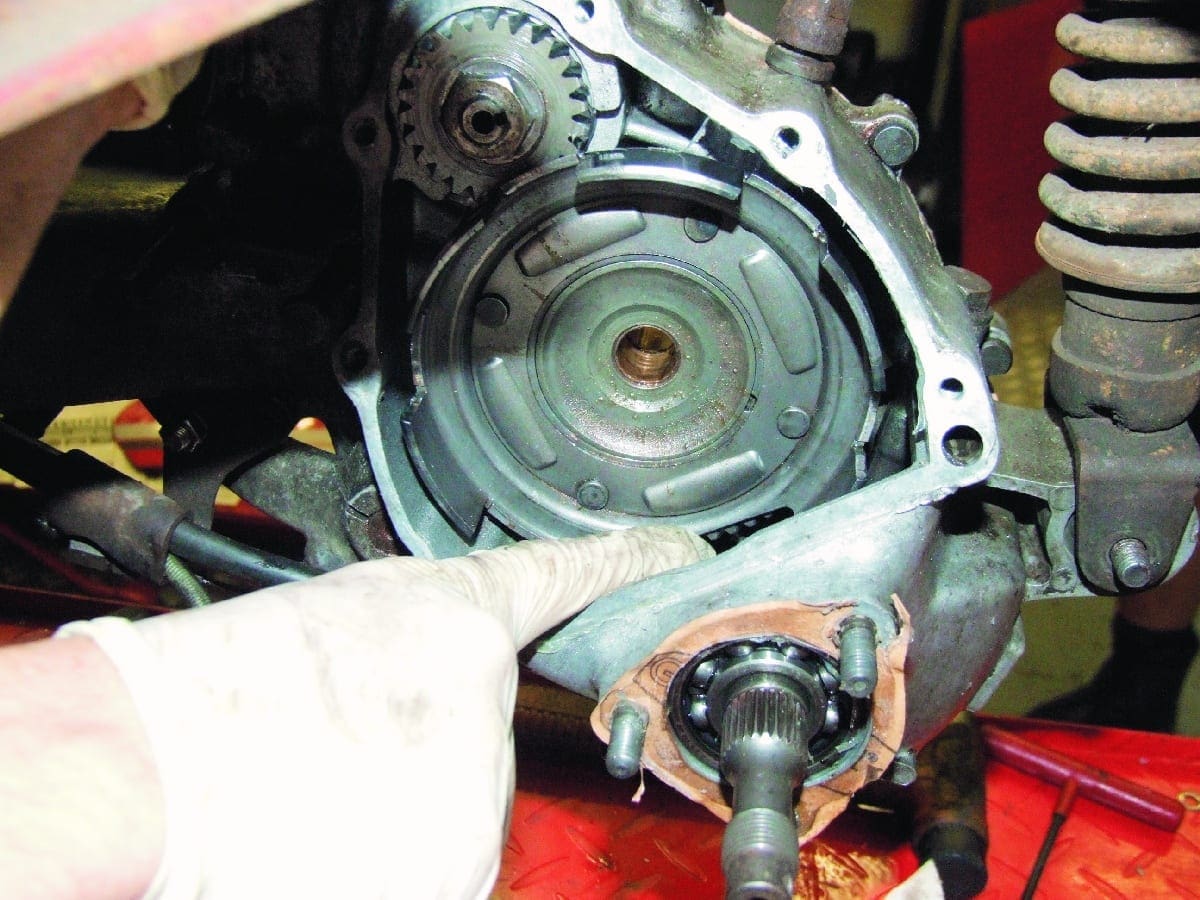

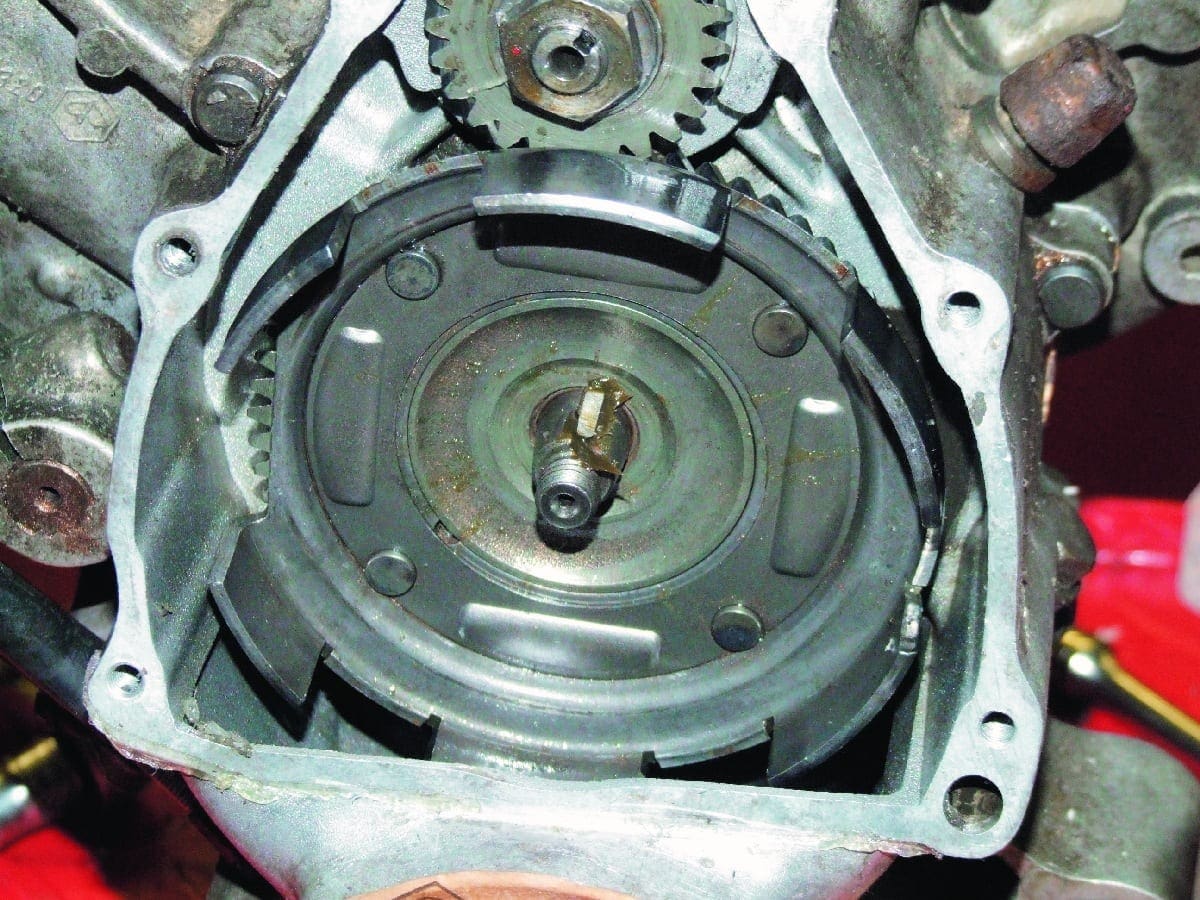

15. Before removing the stator plate you must undo all the connectors (either individual wires or a single plug, depending on model). Then, mark the plate, to ensure the lining is correct on reassembly before undoing the screws and gently feeding the wires through the casing on removal.

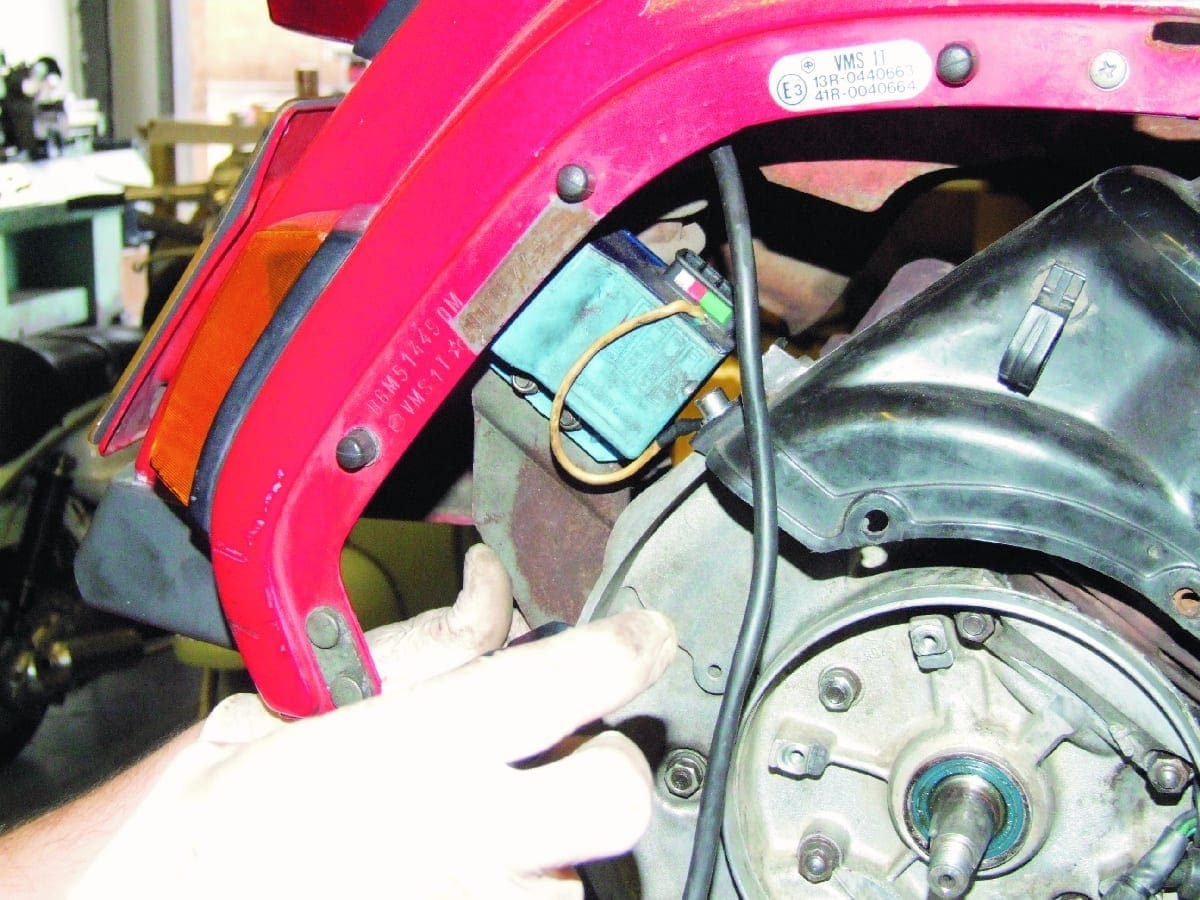

16. Before dropping the engine down you need to remove anything else likely to foul on the frame. ln this instance the CDI unit is vulnerable and if not removed first is likely to be damaged If you simply let the engine swing free.

17. With everything undone, no ancillary components in the way, the frame chocked up and a piece of wood under the engine, you can now remove the rear suspension bolt and let the engine gently swing down until it reaches the supporting block.

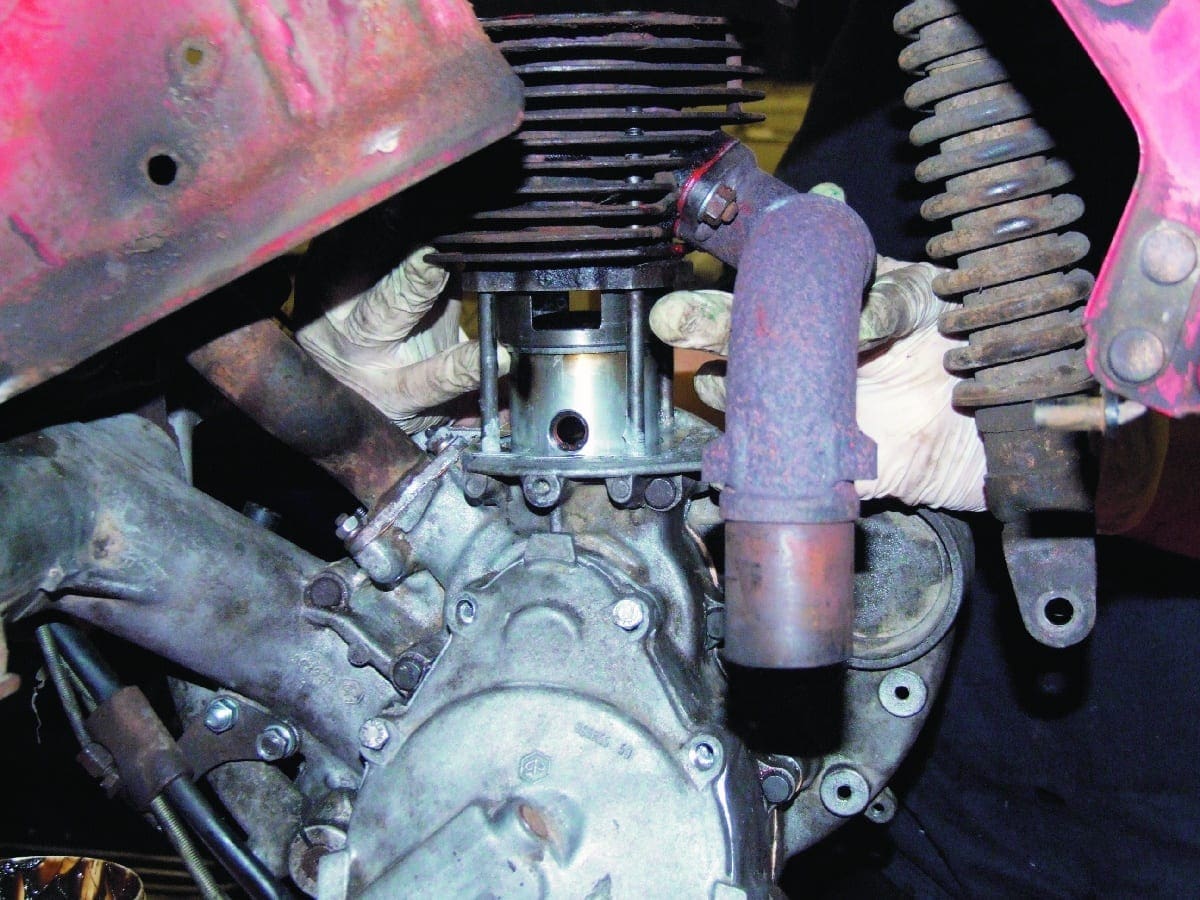

18. The first part of stripping the engine is to remove the top end. Undo the four nuts (working diagonally} that secure the cylinder head then carefully slide the barrel over the piston and off of the engine casing. And don’t forget the base gasket too!

19. With the top end removed it may prove easier to lift the engine back into position, securing it with the suspension bolt. Then begin to remove the casing studs. Note that a number of these can only be accessed from the clutch side of the engine.

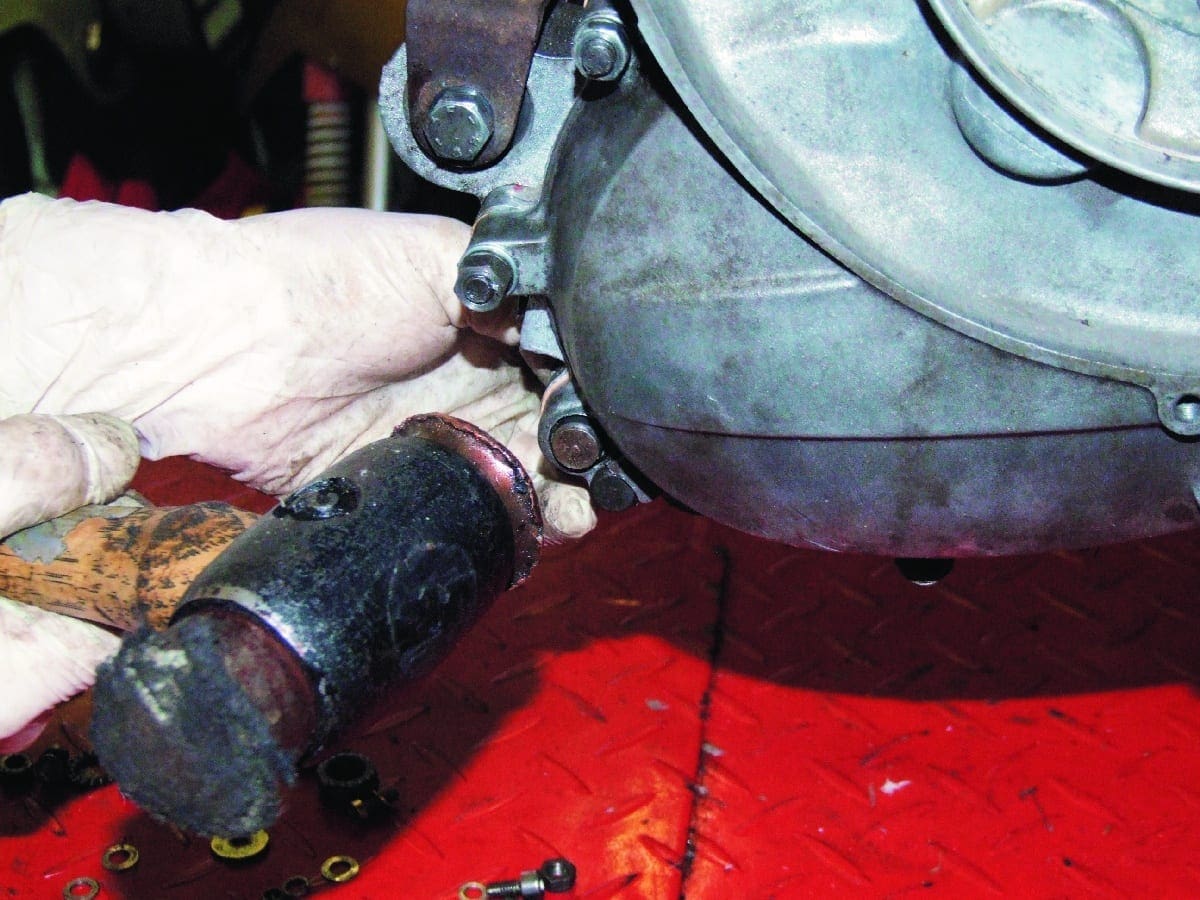

20. With all the bolts undone the casings will hopefully come apart with nothing more than a persuasive wiggle. If this doesn’t work, gently tap the sides, working around the casing with a rubber mallet. Do NOT try to prise them apart or use a heavy hammer. Just take things slow and steady to avoid damaging anything.

21. Slowly turn the layshaft until the cutaway in the clutch basket is almost at the bottom, at approximately ‘5 o’clock’, so it’s sitting over the shaft. Then, gently tap the shaft out from the clutch side with a soft copper mallet, making sure you support it from the other side.

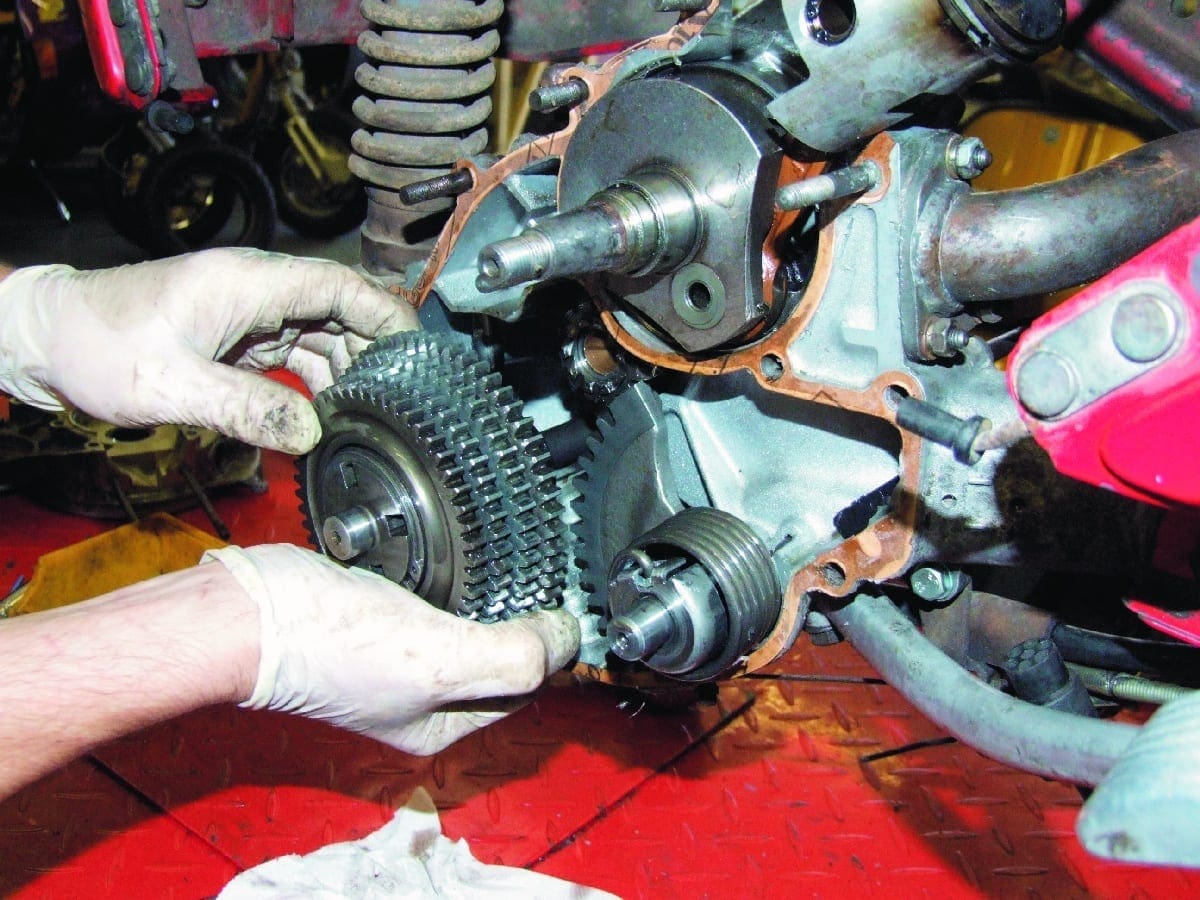

22. With the shaft almost out, take the gear cluster in both hands and ease the final part of the way manually. Note that the gear selector arm stays inside the engine.

23. Place the shaft into a vice (protecting it with pieces of aluminium if possible), remove the gear-retaining circlip and shim and then take off the gears, laying them down exactly as they came off to ensure they are replaced the correct way around later. A tip here is to tie a piece of string throughout the cluster, just in case they get knocked over on the bench.

24. With the gears removed, turn the shafts upside down and remove the circlip and shims at the other end. This allows you access to the gear selector that slides up and down the shaft.

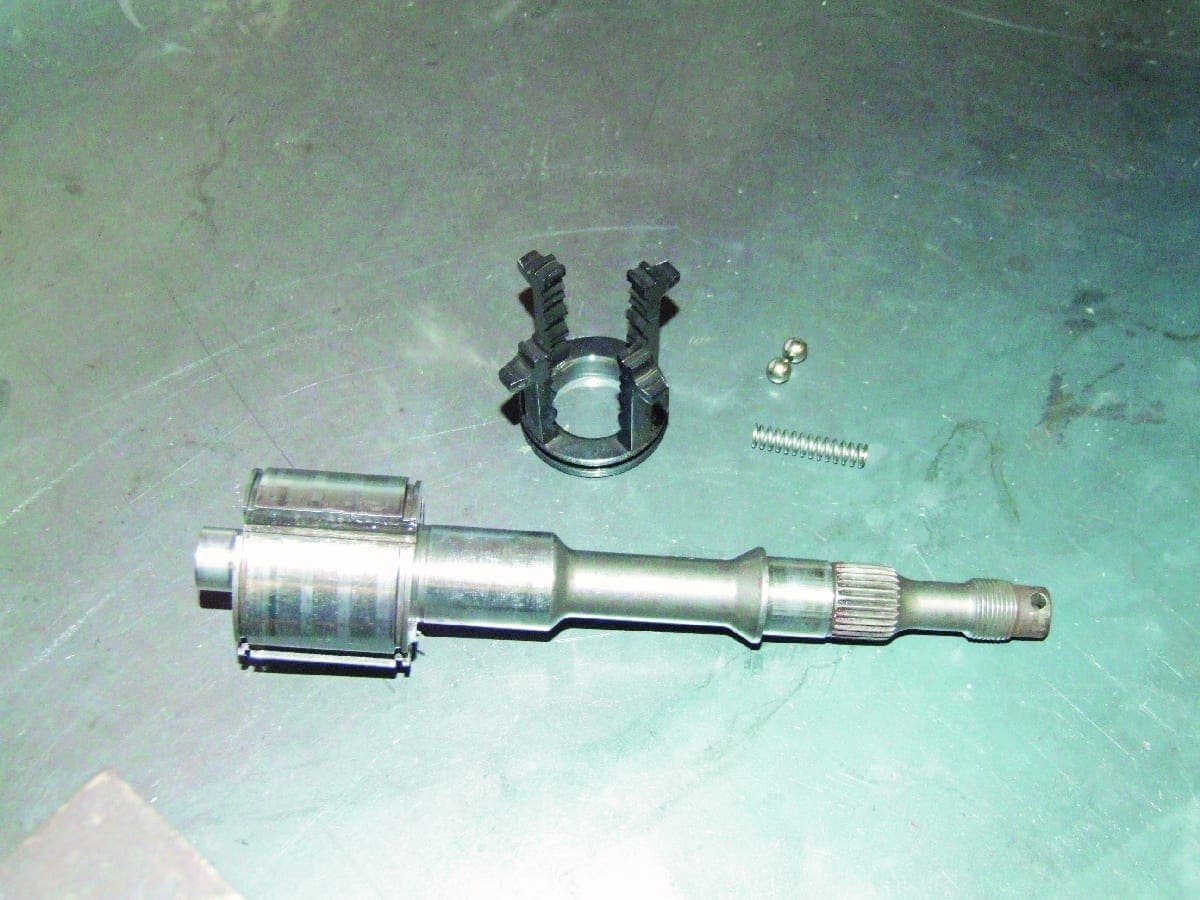

25. With the circlips removed you can now slide the selector of the shaft, but beware of the ball bearings and spring inside which the selector locks on to at stages throughout the gear change. Use a rag or a piece of paper wrapped around as shown to prevent them launching into orbit upon release.

26. And here it all is; selector, shaft, spring and balls. Not a lot to it really, is there? Just damn awkward to get to!

27. The cause of a jumping gearbox is pretty much the same across the board. There is either damage to the gears in question, as shown here, or the selector itself has worn down over the years. It is often manufactured of a softer metal and designed to wear out before the gears meaning just one, cheaper part needs replacing rather than a whole gearbox, in theory.

28. Note that there are a couple of varieties of smallframe selectors on the market, depending on the model you have. The easiest way to tell the difference is by comparing the little arms indicated here which has a square comer both top and bottom for earlier smallframe models, but the one shown here has a curved upper corner suggesting it is for later models such as the PK. If in doubt ask an expert rather than fit the wrong one.

29. Before reassembly, check that the new selector slides up and down the shaft freely. If not, take come fine wet and dry paper to any guilty burrs. Once ready, offer the selector at an angle to the shaft and drop one bearing in from the top, using the selector’s lower leg to retain it.

30. Next you have to insert the spring AND the other ball bearing, then get the selector legs over to secure it all, without removing your eyes! It’s all in the wrist and different people have different techniques. Here we have the ‘keep the ball in with a thin screwdriver and then quickly slide the selector leg over’ method, which worked second time around. Safety googles recommended!

31. Reassembly is pretty much a case of doing all the above but in reverse order, and using new gaskets, seals and bearings where applicable! There are a couple of tips though that we can pass onto you. Firstly as you replace the gears, if you are in any doubt as to whether they are the right way around or not, move the selector through each one to make sure they marry up.

32. The next tip is to temporarily replace the rear hub backplate. This is also a bearing retainer and will assist the replacement of the shaft by keeping the bearing in place as you tap it home.

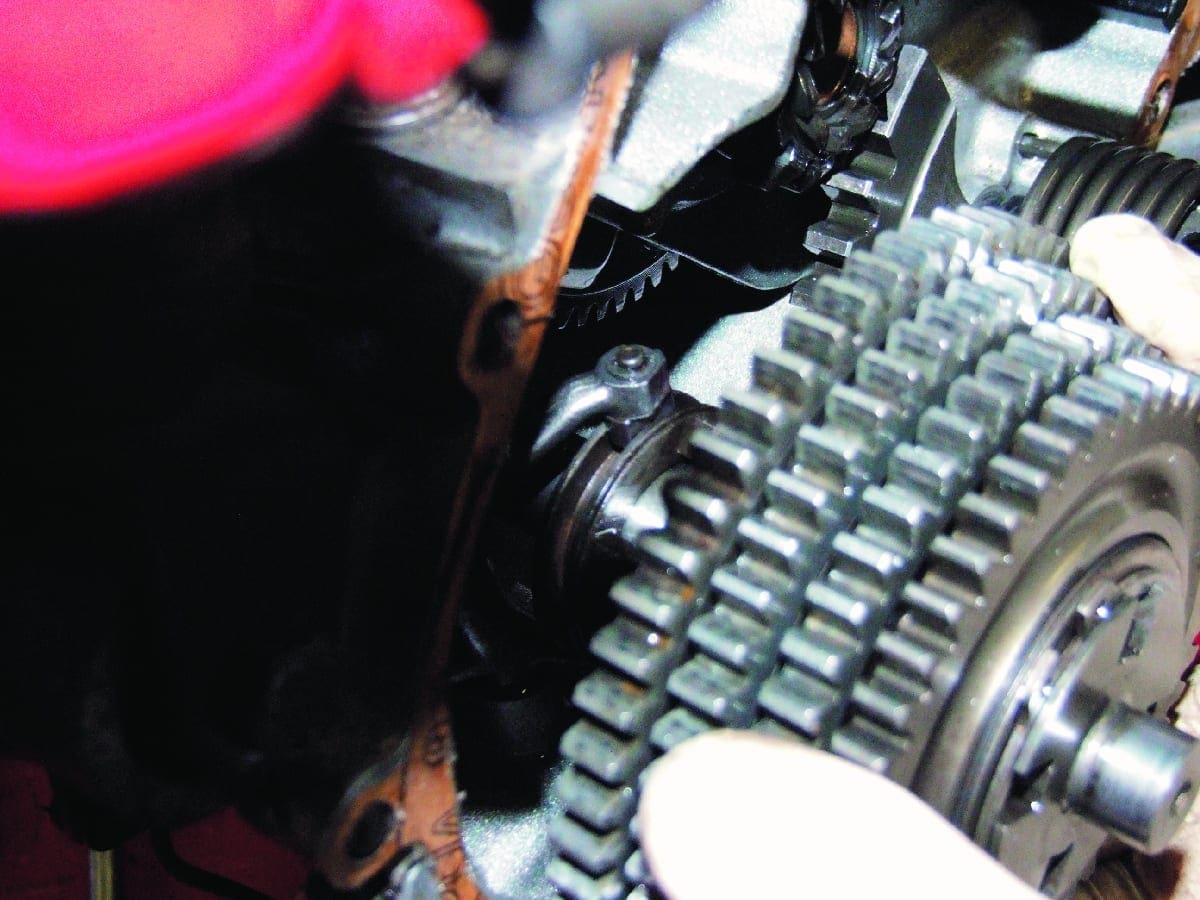

33. Before offering the shaft back into the engine select first gear so that when you offer it up to the gears elector arm in the engine shown here, it’s easier to mate them. Also make sure that the gap in the clutch basket is at the bottom again to allow the shaft space to pass through. If it needs assistance, use a copper mallet and rotate the cluster as you tap it home.

34. To help you locate the gearing when reassembling the engine casinos, clamp a pair of mole grips to the very end of the lay shaft (note they are attached to the plain split pin lip and not the threaded bit!). Use these to tum the engine as the casings are replaced.

35. Only do the engine-casing studs up fingertight at first, until the locating dowel has been replaced. Once this is done the bolts can be fully tightened up, safe in the knowledge the dowel has located the casings correctly.

36. The final tip is to turn the engine by hand so the keyway is at the top then secure the woodruff key in with some grease. Use a torch to locate clutch correctly on the key, than tighten up, using the copper coin again to lock it. Then reassemble the rest of the engine and off you go, hope fully no longer with a hop, slip and a jump!