While routine maintenance usually includes items such as tyre pressure and brake checks, one thing that can often be overlooked is the symptom of erratic tick over. The reason for the symptom needs investigating…

Diagnosis and repairs are all fine at home in the garage, but what if you are out on the road… especially a long journey. Well though there are many causes for an erratic tick over to suddenly manifest itself, some are easy to investigate and sort, avoiding an expensive engine rebuild. Here we look at some of the causes that are fixable at least to get you home with the scooter till a full repair can be made.

Why is it important to investigate the cause?

If all of a sudden your engines tick over either becomes erratic or you are unable to set it correctly then there is a reason for it. There are many possible causes which we will look at in due course but what it is suggesting is that there is either an air leak somewhere or a component failure. This will result in the engine running weak and lead to more dire consequences such as piston seizure or holing of the piston.

One of the main problems I found when servicing customers’ machines was that the engine tick over was quite often set wrong in the first place. If this is the case then it doesn’t leave you much chance of knowing if it does go erratic. So first and foremost make sure your tick over is set correctly. The best way to do this is to get the engine fully warmed up and then slowly lower the tick over with the screw until the engine idles as low as possible without stalling.

If the engine is running fine it should be possible to get the engine to tick over at around 900 to 1100rpm. A good test is to select first gear with the clutch fully depressed as there will now be slightly more resistance, If the engine still ticks over that’s fine; if it’s too low then it may stall. If it does stall, slightly raise the tick over until the engine will tick over with 1st gear selected with the clutch fully held in. The other thing to learn is to get used to your engine noise in tick over mode. No two engines are the same and with different carburettors and exhaust systems, the engine note of your Lambretta will be unique to you. There can be slight deviations to tick over settings; for example in the middle of winter in the cold the tick over will be different to in the middle of summer when it is hotter. As long as you can fine tune the tick over with only a small adjustment on the screw then don’t worry about it. Only when tick over is erratic and unstable do you need to investigate the cause.

Where to start

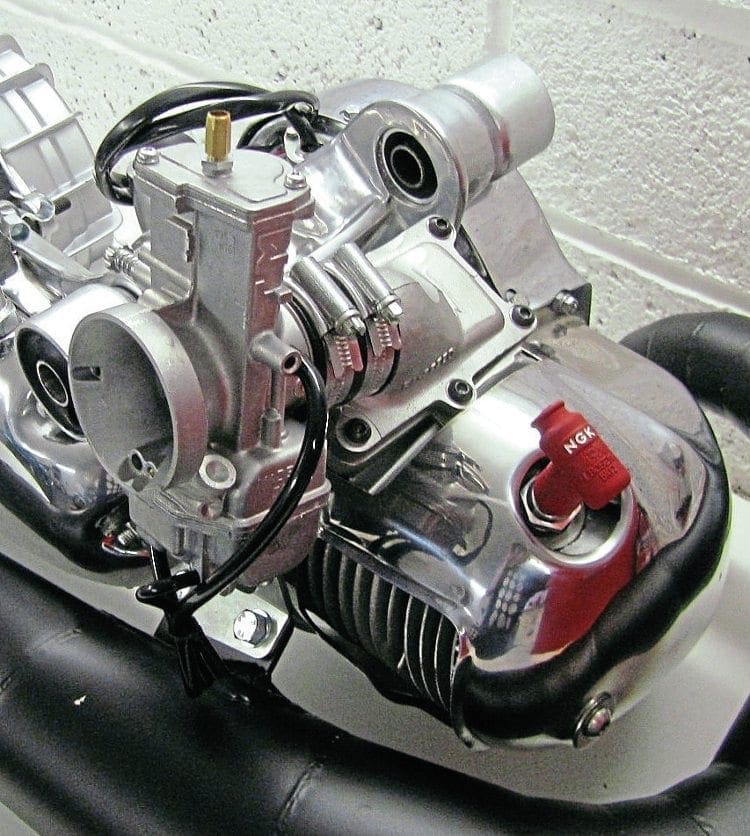

As the tick over is governed by the carburettor this is the first place to look should any problems arise. Start off by checking that the top housing is secure. This varies according to make and model. On many Dellorto carburettors, it is usually two screws or bolts which secure the top, same with the Mikuni. Check they are fully tightened, because if not an air leak can occur causing the erratic tick over symptom. Some Dellorto models will have a threaded screw top similar to that of the Amal MK11. The Amal MK11 was renowned for the top coming loose and in many cases owners secure it with a jubilee clip to alleviate the problem.

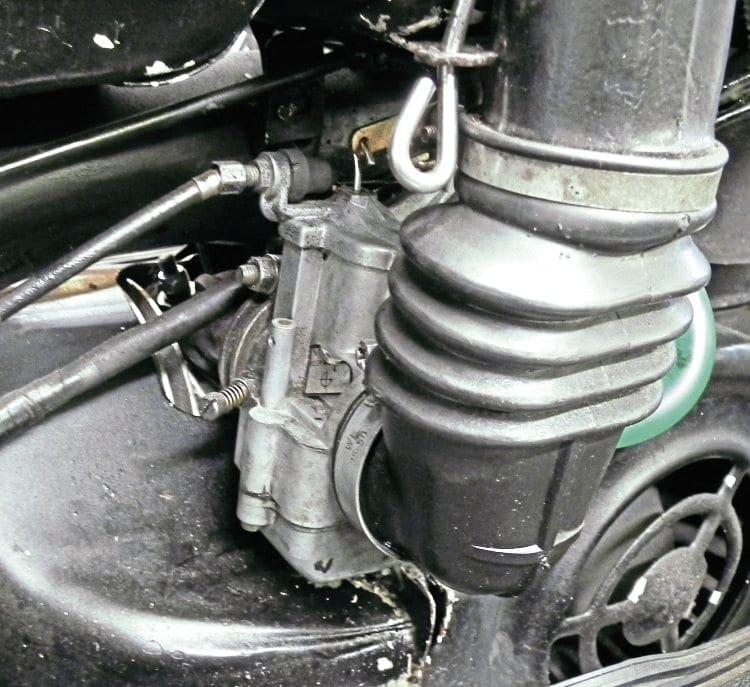

If the carburettor runs through an air box then check that the air hose has not split. If it has then excess air can get in, throwing the jetting out. This will result in the engine possibly running weak without you noticing as the tick over doesn’t always go erratic when this problem occurs. However, you will probably notice a slightly bigger induction roar as more air is sucked in.

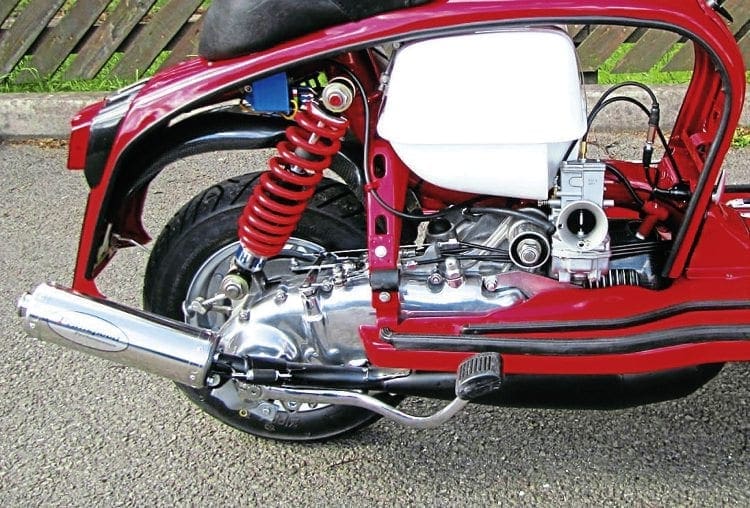

The next place to look is at the mounting onto the inlet manifold. If the carburettor uses the pinch bolt method for fixing, make sure it’s fastened tightly and that there is no movement. If the carburettor is rubber mounted, again check there is no movement but also that there is no split in the rubber itself. If the rubber has split it might be because the main body has been rubbing on a side panel or the petrol tank. Always make sure a rubber mounted carburettor is free from obstruction. If it isn’t then the rubber can split while the engine is in use and may go unnoticed until it’s too late, for example on a long motorway journey. If possible always carry a spare rubber mount as they are easy to change and will allow you to carry on your journey.

Now check the manifold onto the cylinder is secure. It is more common for a double bolted manifold to come loose than a reed valve manifold that has several fixing points. There only has to be the slightest gap and the inlet gasket will disintegrate in an instant causing air to suck in at a rapid rate. If this has happened while out on the road, tighten up as much as you can even though both fixings are not always accessible.

Finally with the carburettor check that the tension spring on both the tick over and air screws are okay and have no obstructions. If they don’t have enough tension then they are prone to self-adjustment through vibration. Though they won’t cause any damage to the engine as such you can save yourself a lot of time and trouble looking elsewhere for the problem unnecessarily. Also, check the choke cable setting and that the plunger fully shuts off. When the engine is cold the choke is needed until it’s warm. If it stays on once the engine is warm then the engine will cut out on tick over as too much fuel is now getting in.

The simple method of testing this is by turning the choke on when the engine has been running for a while if it cuts out then you will know the plunger is shutting the jet off and can be ruled out for causing tick over issues.

Exhaust system

The next potential area to create a tick over problem can occur through air leaks from the exhaust system. Whether it is a standard fixed type of exhaust or multiple-jointed expansion pipe, leaks can occur for several reasons. The first thing to do is look at the fixing to the cylinder first and then back through the rest of the pipe.

The most likely issue is a loss in back pressure and so causing erratic tick over by the manifold being loose on the cylinder. Lambretta engines can be prone to this as there are only two fixing points on the manifold. With a standard box pipe, only one of the 11mm retaining nuts is accessible. If that nut is loose then chances are so it the inaccessible one. If so, tighten it up to get you home but then remove the head cowling and fully inspect. On most stub mounted exhaust systems both nuts are accessible so much easier to tighten. Take care to make sure that the gasket has not started to burn away and if it has you will need to change it once back home. Don’t just tighten up the stub and think it will be okay. Assuming the exhaust is fixed securely at the manifold then check along the main body for cracks or splits in the exhaust. This can usually be identified by a much deeper exhaust note but it may be the case that the foot board will need removing to fully inspect the main body. Look out for oil leaks from the side of the exhaust as the source will reveal where any potential cracks are.

With the engine on tick over it is possible to place a rag over the end of the exhaust and see if it cuts out. If it doesn’t then this suggests exhaust gases are leaking from somewhere. This is only an ad-hoc method of checking on the roadside, take great care as the exhaust gases will be hot.

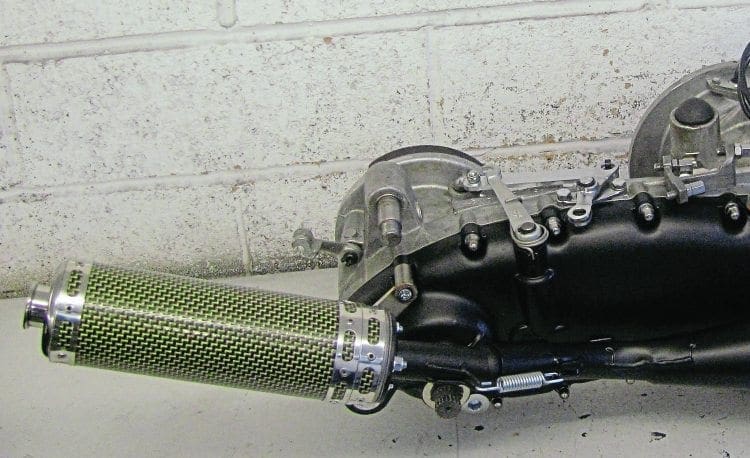

For those who have an expansion with a bolt-on end-can, check all fixings are secure and there is no blow-by where it bolts on to the back section. Some end-cans come riveted, again check that the rivets have not come loose. If they have then the can will need re-riveting or replacing.

Finally where there are spring mounted joints make sure the spring has not come off. Also over time, a spring can lose its tension so check at regular intervals and replace when necessary. A good tip is to carry a spare spring just in case one pops off on a long journey. Not only will this make sure the joint is sealed but will also stop the exhaust from coming loose because there is too much movement from the joint flexing.

Final prognosis

Presuming you’ve made all the checks possible, should the symptoms of erratic tick over still persist then something more problematic may have happened. This can be anything from a warped cylinder head to a crack in the casing. As you’ve looked at all the reasons that are accessible then the best answer is to get your machine recovered home. Even if you do find the answer, for instance a loose barrel stud, this type of repair can’t be done on the side of the road so recovery will be the only option. Remember, carrying on and ignoring these symptoms can be costly, ignore them at your peril!

Finally, get used how your engine runs and sounds and become accustomed to it. If the induction tone is deeper or the exhaust note quieter then something has happened. Likewise, if the engine is racing or tries to cut out something has altered within the parameters of what was the normal running tolerances before. Beware, as these faults can rapidly escalate into other and often expensive problems or failures.

Words & Photographs: Stu Owen