Words: Stu Owen | Photographs: Stu Owen, Martin Murray & Ashley Scott

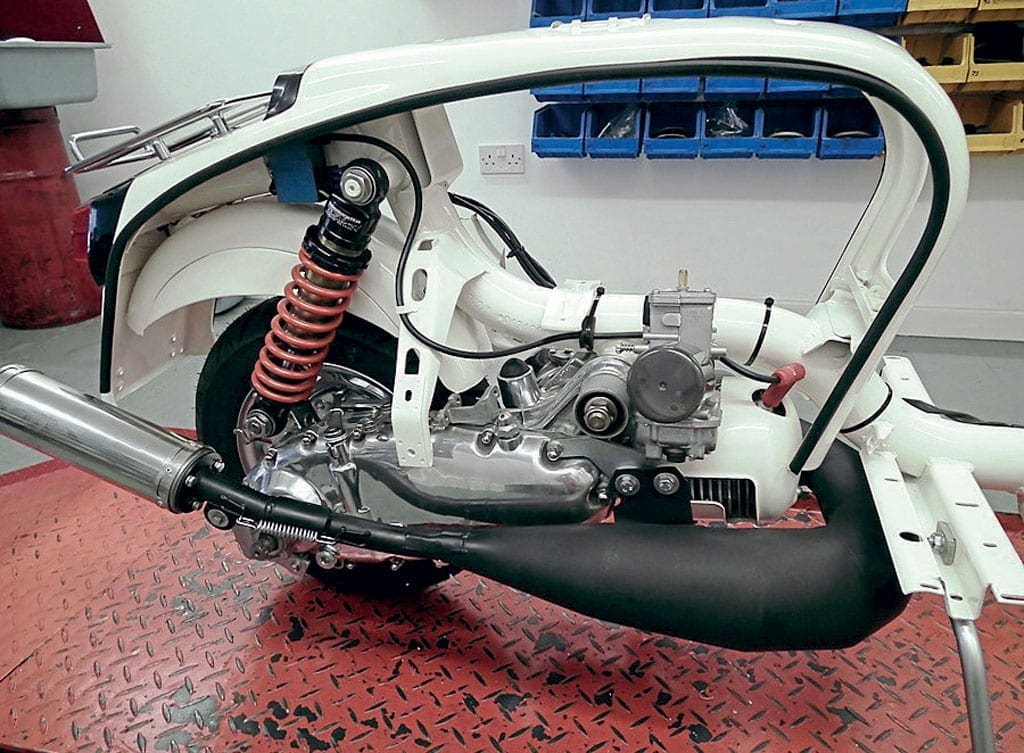

The engine is the heart of your street racer and probably the most complex part. Making the right choice of which powerplant to use is essential…

The engine is, in reality, the whole thing a street racer is built around. Quite often it is said by many owners: “This is the engine I’m building – it just needs a scooter worthy of it going in.” That’s a true statement to a certain extent but the problem remains, what engine should you choose in the first place? This depends on several things and the most important factor is the cylinder kit that is fitted.

This is where it all begins with the rest of the engine components following this decision. Before you start there are several things that must be taken into consideration to make your choice easier.

Which top end?

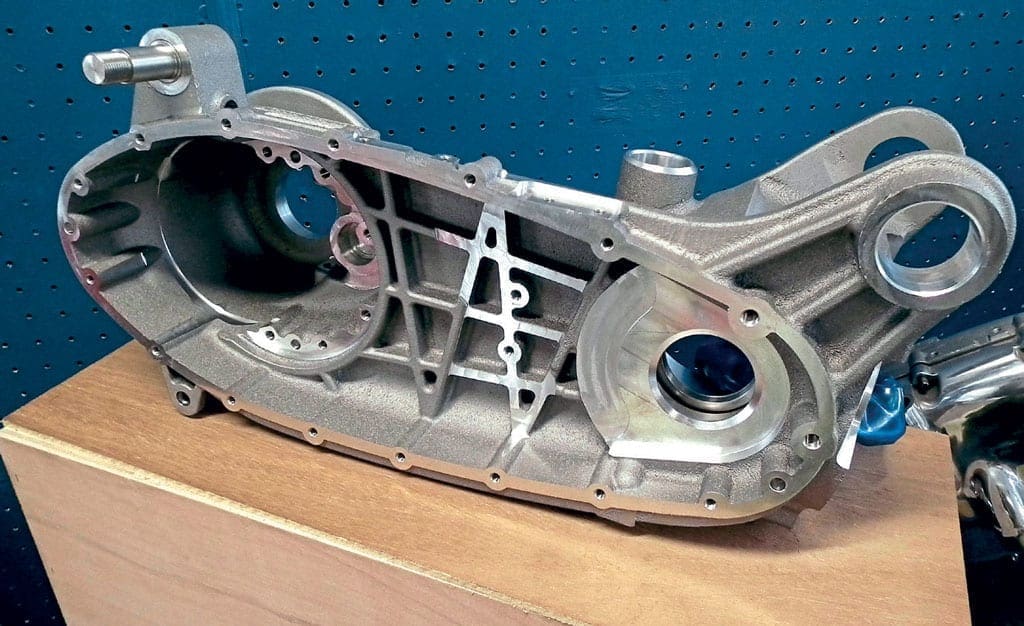

Deciding on which kit to use can be a real minefield and at the best of times very confusing. It can be narrowed down by several factors, the first of which, certainly when it comes to the Lambretta, is the casing. It may be that the engine and frame are the same ones that came out of the factory together and you have documentary evidence to support this. Rather than split them up you want to keep them together.

If it’s a Lambretta and a small block casing then this narrows your choice down, making the decision of which kit to use easier. It may be that you want to use a ‘one-off’ cylinder made exclusively by a tuner which again significantly narrows the choice down.

It’s the final option which is the trickiest buying one of the many available on the market. So which one do you choose? And then, do you have someone else try and get even more bhp out of it? Ask yourself, do I want an engine that is fast but also reliable as it will be used regularly? Or do you want the most powerful engine that it’s possible to build and don’t care about reliability issues? Only you can decide but each time think about exactly what you want it to do, narrowing the options down.

When it comes to how good a kit is, it doesn’t always depend on the manufacturer. For instance, you can have a good kit but fit a poor crank or bearings and it’s something else rather than the kit that lets you down. Perhaps an air hose has split, causing the piston to hole and you read about it. It’s not a fault of the kit but an outside problem causing it to fail.

Be very careful of what you read about certain kits’ reliability on the social media and don’t take what you read as gospel. Where you do need to do your homework is on the power it produces and how accurate the claims are.

Remember a manufacturer has to sell their product and the more impressive it sounds the more it will lure the public in. Take the TS1 as an example. A good standard one will produce 20bhp. However, each engine they are fitted to will give different readings depending on what else is used.

Exhausts, Ignitions, carburettors and so on will all determine the power it creates. Then there is the build itself and how exact the tolerances the person doing it uses. Each engine built may have a slightly different squish band for instance, fractionally altering the power produced. Even if the build is good the next engine produced, even if it’s using the exact same components, can be slightly different.

Beware of seeing readouts from dyno graphs to make your mind up which kit to use. A graph showing an engine reading 30bhp sounds good but it may have been leaned off to get the result. When back on the road it may need an alteration to the jetting. This is to prevent it from seizing or ‘blowing up’ as it’s often described, which may make it lose several bhp and not look quite as impressive.

The reality is, if you are building an engine and it’s producing over 25bhp it’s going to have a good turn of acceleration and top speed. If you want even more, in all honesty, it will be down to the tuner to get the results required. Remember though they will want to use certain components to achieve what you’re asking from them which is fair enough.

Perhaps they require a certain carburettor or exhaust, so bear this in mind to make sure they fit exactly in the space provided during your dry build. It’s no good after the bodywork is painted realising the exhaust the tuner wants to use doesn’t fit in the space provide meaning you have to use an option that may not give such a good result. This is why it’s imperative you know what engine and what components you are using even before the dry build starts, to prevent this kind of situation from happening.

Regardless of which kit you choose and how much power is created, only use the best components possible to go with it. Treat the top end as a different entity to the rest of the engine. It doesn’t matter whether it’s the crank, bearings, oil seals even gaskets – make sure they are of the utmost quality and are tried and tested. Any failure in this area is costly and sometimes fatal to the engine.

Transmission

Next is the transmission and again an area that can throw up loads of choices which can easily confuse. For the Vespa, it uses a direct drive system and there isn’t great scope to alter things very much. The main options on a PX casing are upgrading the clutch and playing primary drive and gear combinations. There are plenty of sites on the internet that give out useful information on what set up to use so study them thoroughly before making any choices.

Remember, altering the gearing by making it shorter or longer will depend on the characteristics of the top end you are using and what and where the power is being created. When it comes to the small frame engine, well, that’s a completely different kettle of fish.

There are so many options not just for cylinder kits but whole engine packages. With small frame racing and tuning so competitive in Europe there are literally hundreds of options you can choose from and far too many to mention here. Again, do your homework and talk to the companies that produce the engines. Taking it even further, look at whose engines are the most successful on the track and that will guide you where you should be looking if you want the best.

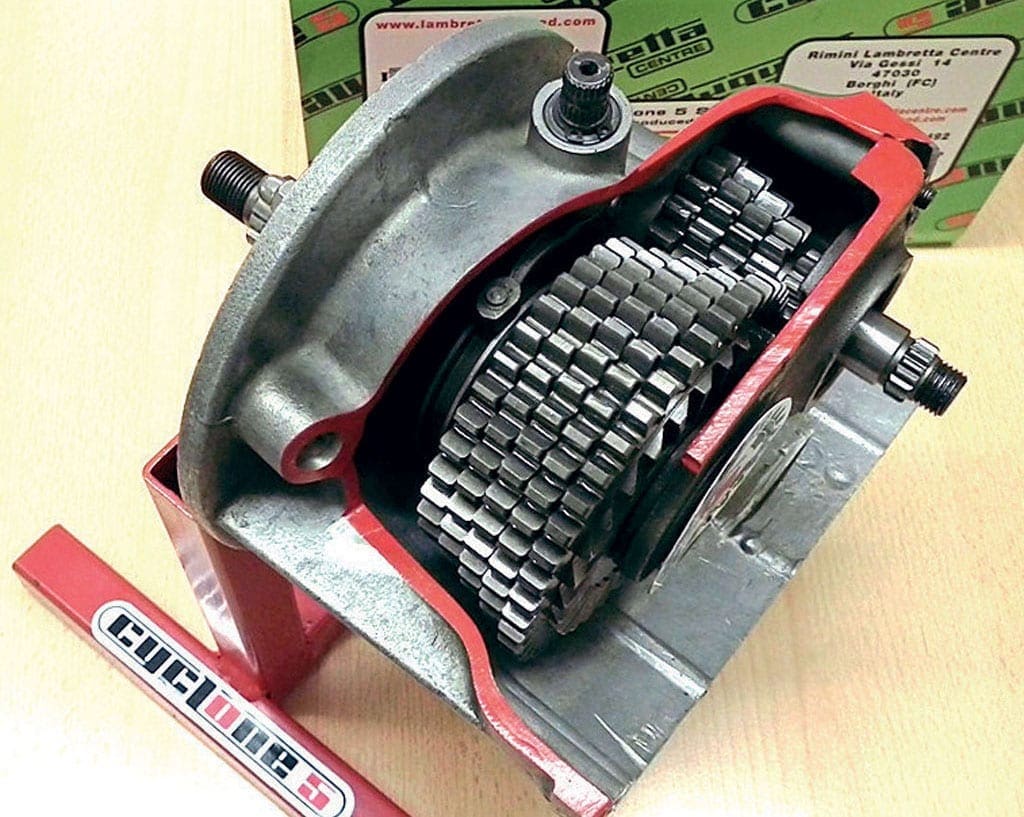

If the Vespa transmission seemed complicated with more choices than you could imagine, then welcome to the Lambretta transmission where it’s almost infinite. The problem stems from the number of gearing options that are available. This is not only because sprocket sizes can be altered as the Lambretta transmission uses a chain drive but also Innocenti made several different gearboxes that are all interchangeable.

With the advancement in five-speed technology over the last decade and with several companies now offer this option, the combinations are even greater than thought possible even just a few years ago. The simple way to think about it is to go off what your top end is creating and work the gearing out from there. If you are still unsure seek advice but beware – everyone will have a different opinion of how to go about it. If possible ask someone who races a Lambretta as they will have the best idea of what you require or your tuner if that’s who is building the engine.

If you are intending to use the engine for long distance rallies and on the motorway you will want longer gearing. If it’s an out and out street racer just for thrashing around on then shorter gearing is best, getting through the gears very quickly. You must take into consideration that if you choose the latter then long distance motorway use will not be easy as you will be revving flat out with a low top speed. It can be a difficult balance to get right. The other option is to change the gearing depending on what you are using your Lambretta for. Not the most practical choice but sometimes the best.

Whatever gearing options you eventually choose, the quality of the parts used in the transmission should only be the best available. Whether its bearings, chains, sprockets or tensioners don’t use something because it’s cheap, use something because it’s good, even if it costs more. For example, the chain; a cheap one laid alongside an expensive one will look pretty similar. Once fitted in the engine and presumably one with a high bhp it won’t take long for the cheap one to wear out or even fail.

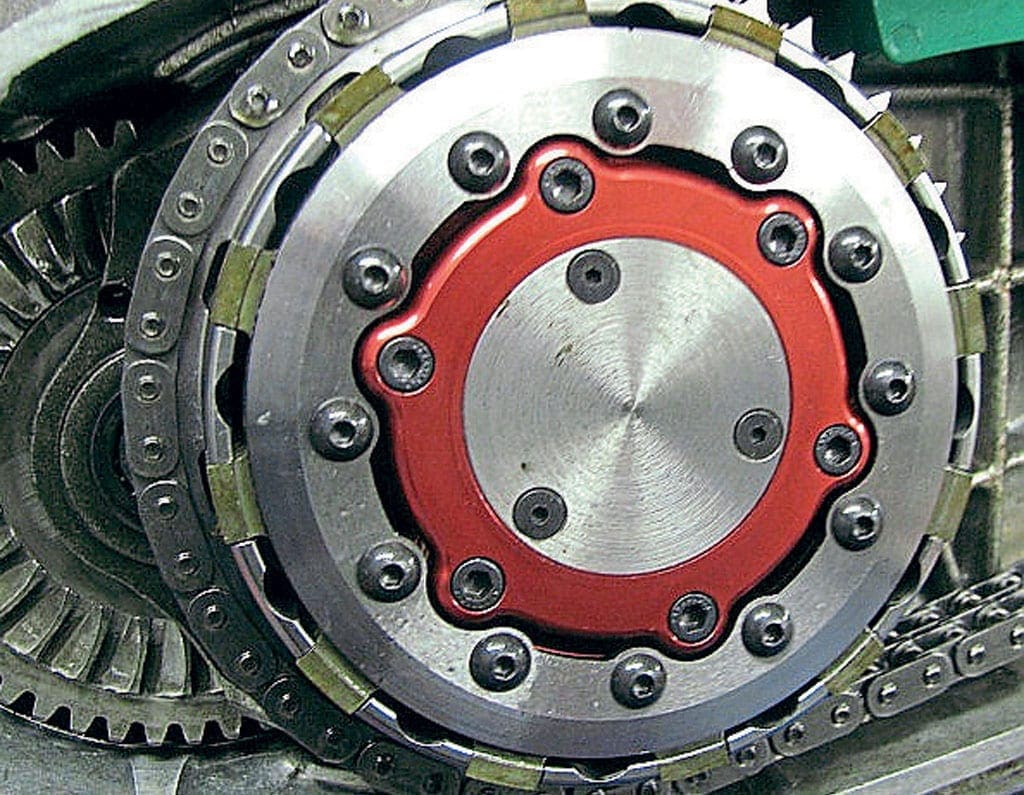

Just like the top end, there should be no compromise in the components and only use the best that is available, a transmission using substandard components will wear out very quickly. The final area for Lambretta transmission and the part that is most prone to wear is the clutch. Again, over the last decade or so this is the component that has been exposed to the most development.

The clutch has a hard life even in the most of tame engines and once it’s struggling to cope with the power being put through it will wear out pretty quick. There are loads of options on the market, all claiming to be the best. For an idea look at the most powerful engines out there and see what they are using. The clutch will need to be good to cope and if your engine has less power then there is your answer – use that one.

Just because your engine isn’t kicking out a massive amount of power doesn’t mean you can’t fit the strongest clutch available; far from it – over-engineer your engine as much as possible, not just with the clutch but every component. That goes for both the Vespa and Lambretta, build the whole engine as strong as you possibly can.

Just because your engine doesn’t kick out high bhp when you build it doesn’t mean you won’t upgrade it at a later point in time. If you do then you will know the over engineering you started out with in the first place will still cope with the extra power you are now putting through it.

The bits on the outside

While the inside of the engine is the most important, what’s on the outside should not be forgotten. Both the Vespa and Lambretta engine with the exception of the odd water cooled example use forced air cooling. While it’s never been much of a problem for the Vespa, as the way the cowlings are fitted is strong, that can’t be said for the ones used on a Lambretta.

Part of this is due to the fact that the Lambretta engine does vibrate more. This is compounded by the fixing points that were originally designed by Innocenti which are pretty flimsy. It is vital that they don’t come loose as the engine will overheat pretty rapidly and seize regardless of how good the engine is set up.

First of all, make sure the cowlings being used are the best available. Some of the remade copies that are produced from certain sources are very thin and even if mounted properly tend to split through vibration. If possible use good Italian examples even though when it comes to the head cowl it will mean having to cut it to prevent fouling on the exhaust or inlet manifold. It’s imperative that there is clearance around these two components otherwise if the cowling does touch it will create excessive vibration and cause even the best quality one to split.

Next is the cable controls which again on a Vespa are pretty versatile and strong compared to the Lambretta where they are prone to wear. Replacing the linkage these days is pretty simple as there are some very good ones now available and an improvement on the original. Many times owners spend thousands on engines but leave this part of the build out.

Poor linkages on the casing, and that goes for both makes, can result in inaccurate clutch adjustment leading to failure of the clutch. Likewise, worn gear controls could mean missing a gear under acceleration and bearing in mind a lot of bhp will be going through the transmission then there is the potential to break a tooth off a gear cog quite easily.

Look at your street racer as if it was a Formula 1 car and make sure at all times that every system on it is working to perfection, not just during the build but also when it on the road. If a part is worn, even something small, change it. The linkage controls on top of the engine are the perfect example.

Sounds too good to be true?

The final part of the engine section is more a warning or piece of advice. As already stated the choice for just about every part of the engine is immense and continues to grow year on year. The market is so competitive manufacturers will advertise their components trying to tempt you in to buying off them and not the opposition. While there is nothing wrong in that, beware of the products that claim to do things that sounds almost too good to be true.

Before buying a component that is making bold claims check it out thoroughly beforehand. It’s pretty simple to do either by looking at reviews or asking the question yourself. The latter can lead to people making all sorts of comments but should give you a good enough idea whether it’s any good or not. No one is saying a manufacturer’s claim isn’t true, but do research first before buying simply because an advertising slogan tells you it is the best thing since sliced bread.

Overview

Some reading this article may have thought it was about exactly how to build a specific tuned engine for your street racer. While that would be good to do, it would take decades to cover all the options available out there. This is a guide into the thinking required of how to go about making the right choices on what is likely to best suit your personal tastes and requirements. No matter what your budget, it’s better to avoid pointless expense and to ensure that you get things right first time.

Many of us have built tuned scooters only to wish we had done it differently pretty soon after it’s finished. The result is to sell it off and start all over again. Some owners may only have one shot at building their street racer so it’s imperative that they don’t make a mistake. As the engine is the centrepiece of such a project the planning and execution of it are essential.