Control cables are one of the most overlooked components on any scooter — right up until they seize, snap, or leave a rider stranded. Despite their apparent simplicity, these vital links between rider and machine play a critical role in safety, feel, and reliability.

British specialist Venhill, which has been manufacturing upgraded control cables at its Surrey factory for more than 50 years, explains why cable design has stood the test of time — and what riders need to know to keep theirs working smoothly.

A design that hasn’t really changed since 1896

The fundamental design of the modern control cable dates back to 1896, when Ernest Monnington Bowden patented a flexible cable system that allowed a sliding wire to transmit movement around curves without pulleys. Remarkably, that basic principle remains unchanged today.

Enjoy more Scootering Magazine reading every month.

Click here to subscribe & save.

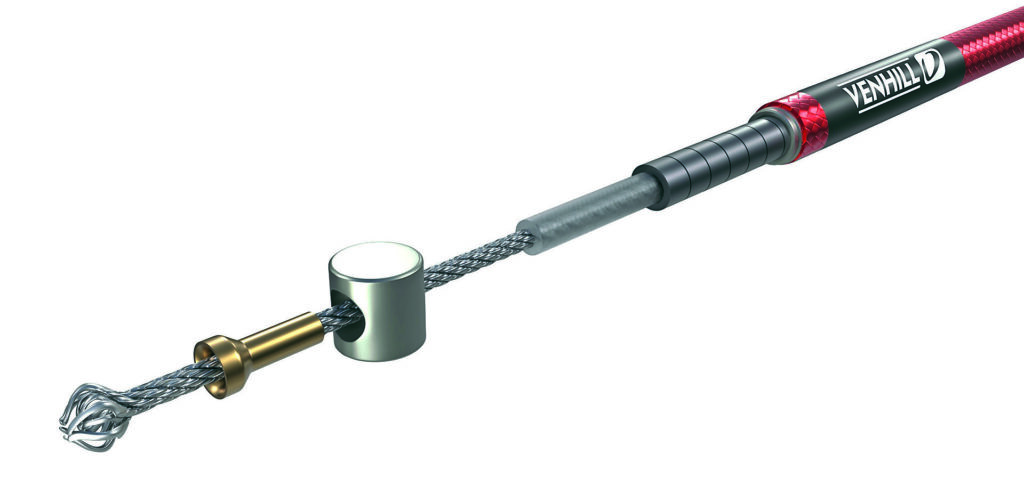

While materials have evolved — including the introduction of nylon and PTFE (Teflon) liners, stainless steel inner wires, and galvanised strands — a modern scooter cable still looks and operates much like one from the 1920s.

What actually makes up a control cable?

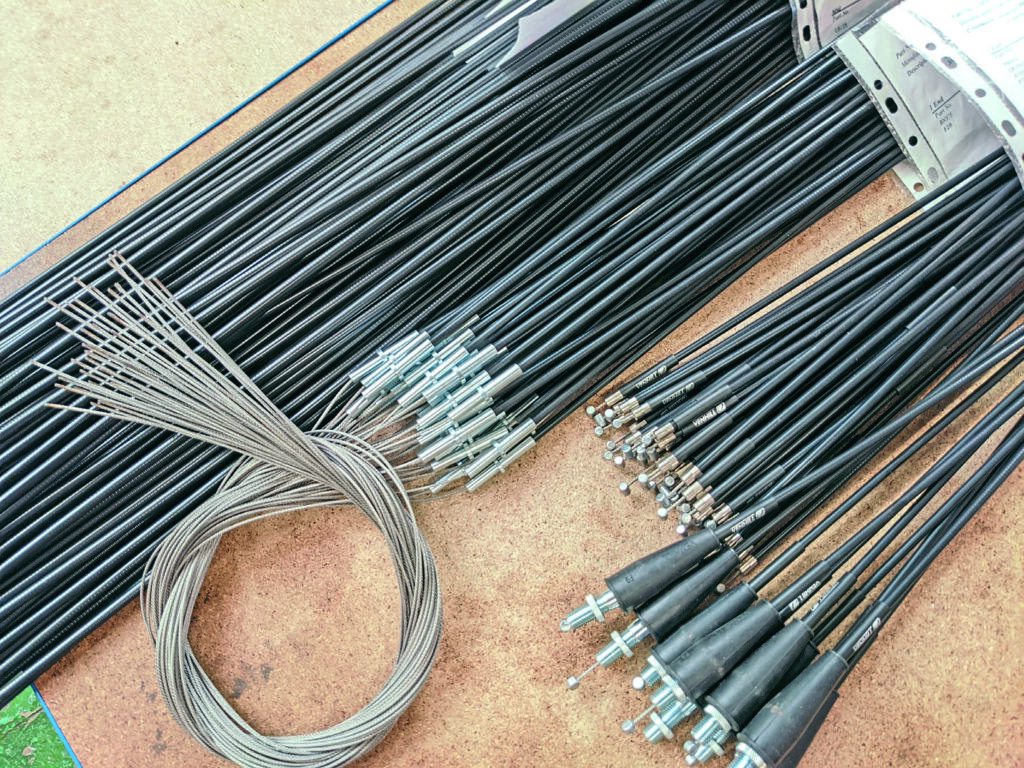

Although cables may appear similar at first glance, quality varies considerably. A typical control cable consists of:

- An inner wire, either a flexible wire rope for throttles or a stretch-resistant strand for clutches and brakes

- A smooth nylon or PTFE liner, reducing friction and improving feel

- An outer conduit, usually a steel spiral wrapped in weatherproof PVC for protection

Higher-quality cables use low-friction PTFE liners and feature bird-caged wire ends, a manufacturing process that significantly increases strength and durability.

Understanding OEM cable numbers

OEM (Original Equipment Manufacturer) numbers help identify the correct cable for a specific model, but years of dirt and wear can make them hard to read. These codes typically consist of two or three sections: one identifying the component type, and the others specifying the exact vehicle application.

For example, a Honda clutch cable marked 22870-KRN-A40 identifies it as a clutch cable designed for a 2012 Honda CRF250R

Why cables fail — and how to prevent it

The most common causes of cable failure are water, dirt, and dust ingress. Pressure washers are particularly damaging, as they force contaminants into the cable while stripping away lubrication.

Routine checks are essential. Stiff or sticky throttle, clutch or brake operation often signals internal damage. Visual inspection should focus on:

- Rust or corrosion at lever and twist-grip connections

- Kinks, cracks, or scuffing along the conduit

- Binding during full lock-to-lock handlebar movement

Poor routing not only shortens cable life but can also present a serious safety hazard

Maintenance, replacement and modern upgrades

Traditional cables should be serviced annually by flushing with WD-40, followed by light oil lubrication. Thick greases should be avoided, as they attract dirt. Exposed nipples benefit from a small amount of copper or silicone grease.

Premium cables, such as Venhill Featherlight, use stainless steel inner wires and PTFE liners, making them effectively maintenance-free and eliminating the need for regular lubrication 017 SC_AUG.

While it is possible to make custom cables with the correct tools and soldering technique, replacement cables are relatively inexpensive. DIY solutions are typically reserved for custom builds or modified scooters where standard lengths no longer apply.

Correct installation matters

Even the best cable will perform poorly if fitted incorrectly. Key installation principles include:

- Carefully documenting the original cable route

- Matching inner and outer lengths exactly

- Avoiding tight bends, heat sources, and overtightened cable ties

- Ensuring smooth operation through the full range of handlebar movement

Correct installation is just as important as cable quality when it comes to longevity and feel.

Original article appeared in Scootering Magazine, click here to subscribe. Dan Sager was the original author, photos from Venhill. Lean more about them here